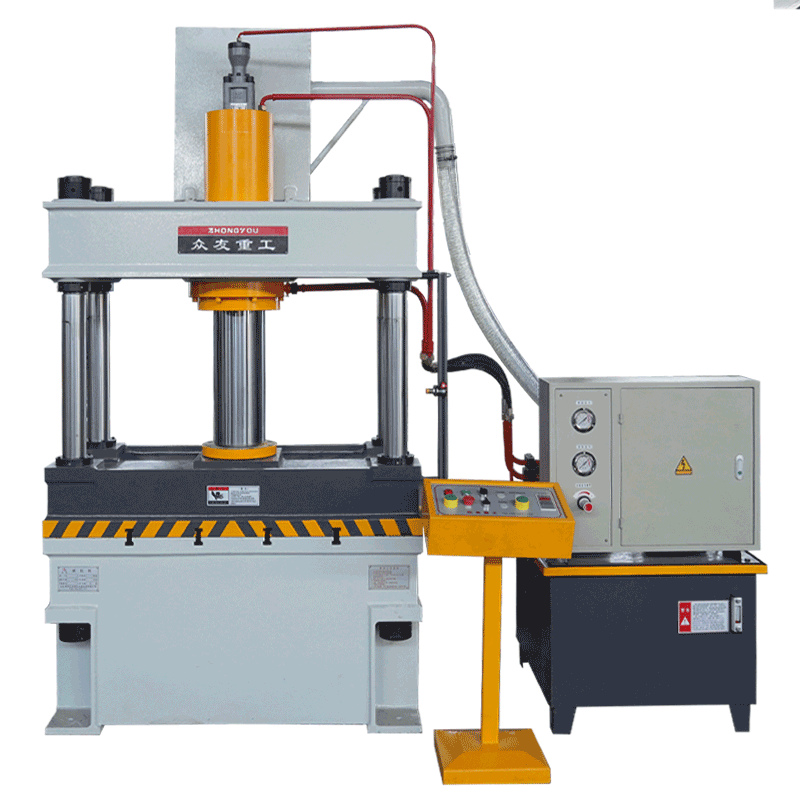

Servo fast three-beam four-column hydraulic press 250 tons water-cooled hydraulic presses

250 tons fast servo hydraulic press” is a combination of servo control technology and hydraulic transmission.It is a high-precision and high-efficiency molding machine that combines servo control technology and hydraulic transmission. Its core features are “fast response, precise control, high efficiency and energy saving”, and it is suitable for scenarios that require high processing accuracy, speed and stability (such as precision stamping, metal stretching, precision molding, etc.).

Description

250 tons fast servo hydraulic press” is a combination of servo control technology and hydraulic transmission.It is a high-precision and high-efficiency molding machine that combines servo control technology and hydraulic transmission. Its core features are “fast response, precise control, high efficiency and energy saving”, and it is suitable for scenarios that require high processing accuracy, speed and stability (such as precision stamping, metal stretching, precision molding, etc.).

Servo motor drive system

Adopting servo motor to directly drive the main drive oil pump, eliminating the proportional servo valve or proportional pump link of the traditional hydraulic press, the system response speed is increased by more than 50%.

Remarkable energy saving effect: according to the processing technology and production beat different, compared with the traditional hydraulic press can save 30% -70% of electricity.

Low-noise operation: internal gear pumps or high-performance vane pumps instead of axial piston pumps, the noise is reduced by 5-10dB; the motor speed is 0 when the slider is stationary, and the noise emission is basically zero, which meets the ISO 11699 standard (≤70dB).

Quick cylinder and cartridge valve integrated control

Dual-cylinder design: the main cylinder provides 250 tons of nominal pressure, and the quick cylinder realizes the rapid descent and return of the slider, with a speed of up to 200mm/s.

Cartridge valve system: pressure and stroke can be adjusted steplessly, supporting both fixed-pressure and fixed-travel processes, shortening the commutation time to less than 0.2 seconds, reducing non-production time by 30%.

Closed-loop control: real-time monitoring of the slider position and pressure through displacement sensors and pressure sensors, deviation correction time ≤ 0.1 seconds, to ensure product repetitive positioning accuracy ± 0.05mm

Views: 0

Compression molding process

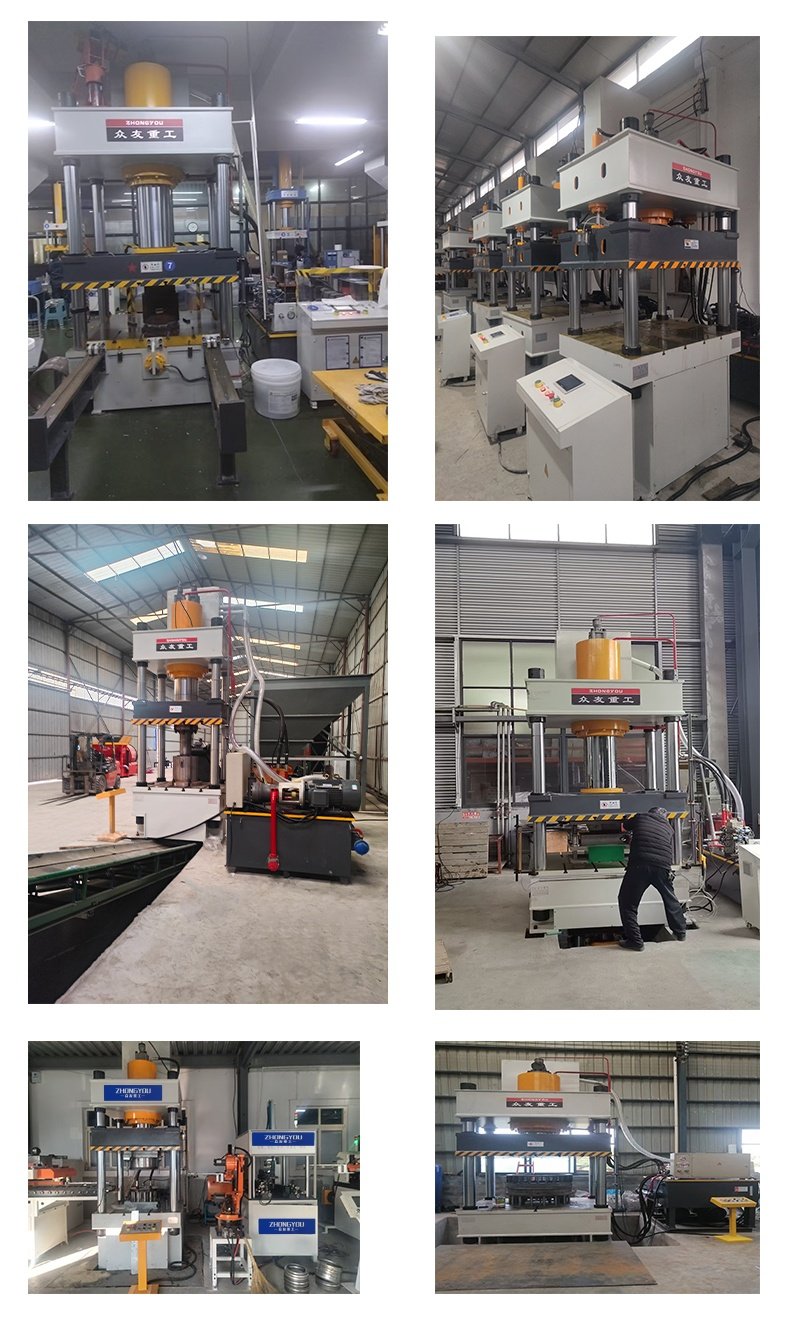

Customer Case

Technical Specifications

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Name | Unit | YQ32-400 | YQ32-500 | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective Area of Workbench | mm | 1250×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 150 | 100 | 180 | 180 | 190 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 7-18 | 10-18 | 6-15 | 6-14 |

| Return Speed | mm/s | 100 | 180 | 200 | 90 | 220 | 200 | 220 |

| Ejecting Force | kN | 630 | 1000 | 1000 | 400 | 1000 | 1000 | 1600 |

| Maximum Ejecting Stroke | mm | 300 | 300 | 300 | 200 | 300 | 300 | 300 |

Detailed Parameters

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Name | Unit | YQ32-400 | YQ32-500 | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective Area of Workbench | mm | 1250×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 150 | 100 | 180 | 180 | 190 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 7-18 | 10-18 | 6-15 | 6-14 |

| Return Speed | mm/s | 100 | 180 | 200 | 90 | 220 | 200 | 220 |

| Ejecting Force | kN | 630 | 1000 | 1000 | 400 | 1000 | 1000 | 1600 |

| Maximum Ejecting Stroke | mm | 300 | 300 | 300 | 200 | 300 | 300 | 300 |