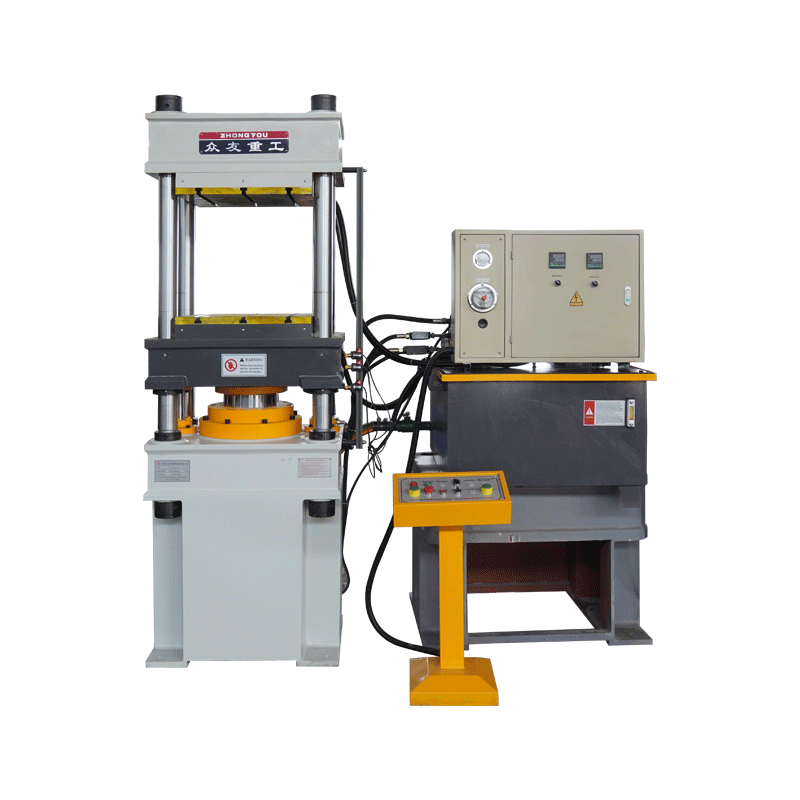

Refractory Brick Forming Hydraulic Press

The 1500-ton hydraulic press for pressing refractory bricks typically adopts a four-column or frame structure, featuring high pressure, high precision, high automation, and multi-functionality. It meets the stringent requirements for density, strength, and dimensional accuracy in refractory brick production, making it suitable for large-scale, high-efficiency forming operations of refractory materials.

Description

The 1500-ton hydraulic press for pressing refractory bricks typically adopts a four-column or frame structure, featuring high pressure, high precision, high automation, and multi-functionality. It meets the stringent requirements for density, strength, and dimensional accuracy in refractory brick production, making it suitable for large-scale, high-efficiency forming operations of refractory materials.

This equipment is primarily used for the compression molding of refractory products, such as magnesia, magnesia-chrome, high-alumina, and clay-based refractories. By applying pressure directly through hydraulic cylinders, it achieves bidirectional equal-pressure compression, multiple high-low pressure cycles, and stable pressure molding. Equipped with a volumetric feeding device, it automates the entire production process from charging to molding to brick discharge.

Views: 0

Compression molding process

Customer Case

Technical Specifications

Detailed Parameters