Zhongyou forklift solid tire press machine for tyre dismount and mount

Different types of tyres and wheels need different tooling, the user to install the tire before the selection of tooling, then the disassembly and assembly operations, it will be very convenient and quick. According to the motion mode and the size of the machine, the machine can be divided into manual press and electric press, which is generally suitable for large tonnage forklift truck or truck tire.

Description

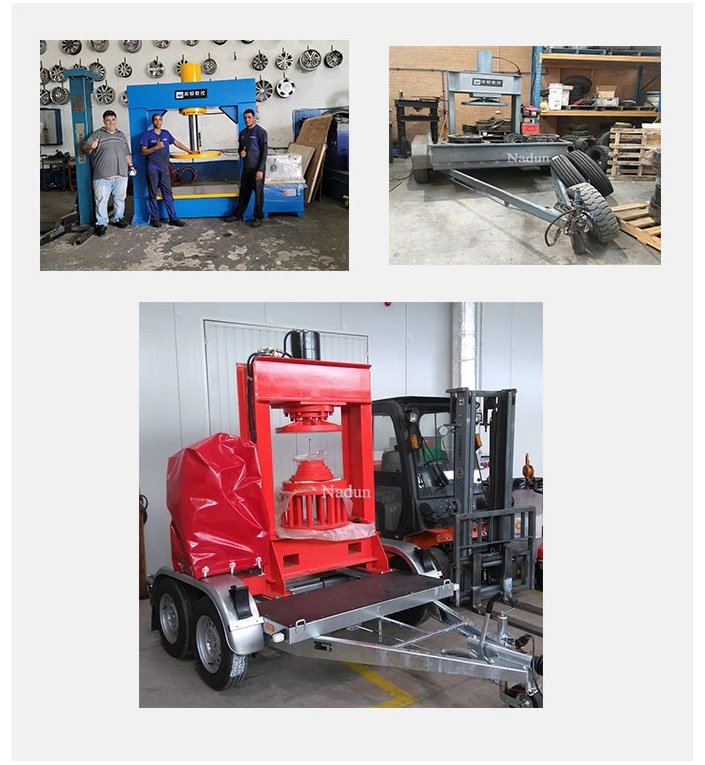

Automatic Forlklift solid tire press machine/industrial tire press

The tire press is a kind of tire disassembly equipment, which is used to disassemble the rim and tire with the retaining ring, and is mainly used for disassembly and assembly of various solid tires. When using, firstly select the tooling correctly, then place the wheel hub on the workbench, press the tool head to press the tire on the tire, press it into the wheel hub, and finally load the snap ring with the guide ring. Different types of tires and wheels require different tooling.

Different types of tyres and wheels need different tooling, the user to install the tire before the selection of tooling, then the disassembly and assembly operations, it will be very convenient and quick. According to the motion mode and the size of the machine, the machine can be divided into manual press and electric press, which is generally suitable for large tonnage forklift truck or truck tire.

How to Use the solid tire press machine?

1.Choose a good tooling correctly,

2.Put the mould on the work table,

3.Put the wheel on the mould, handling pressure head to Press the die on the tire

4.Finally with the boot ring loaded.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Tonnage | Working Pressure | Cylinder Diameter/Rod Diameter | Effective Table Size | Opening Height | Stroke | Pressing Speed | Return Speed | Motor Power | Oil Pump Specification |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000×800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (fixed) |

| 120 | 31.5 | D220/d110 | 1000×800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (fixed) |

| 160 | 31.5 | D250/d150 | 1400×800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (fixed) |

| 200 | 31.5 | D290/d160 | 1500×800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (fixed) |

| 250 | 31.5 | D310/d180 | 1500×800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| 300 | 31.5 | D360/d220 | 1500×800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

Detailed Parameters

| Tonnage | Working Pressure | Cylinder Diameter/Rod Diameter | Effective Table Size | Opening Height | Stroke | Pressing Speed | Return Speed | Motor Power | Oil Pump Specification |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000×800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (fixed) |

| 120 | 31.5 | D220/d110 | 1000×800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (fixed) |

| 160 | 31.5 | D250/d150 | 1400×800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (fixed) |

| 200 | 31.5 | D290/d160 | 1500×800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (fixed) |

| 250 | 31.5 | D310/d180 | 1500×800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| 300 | 31.5 | D360/d220 | 1500×800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5kw | 40McY (fixed) |