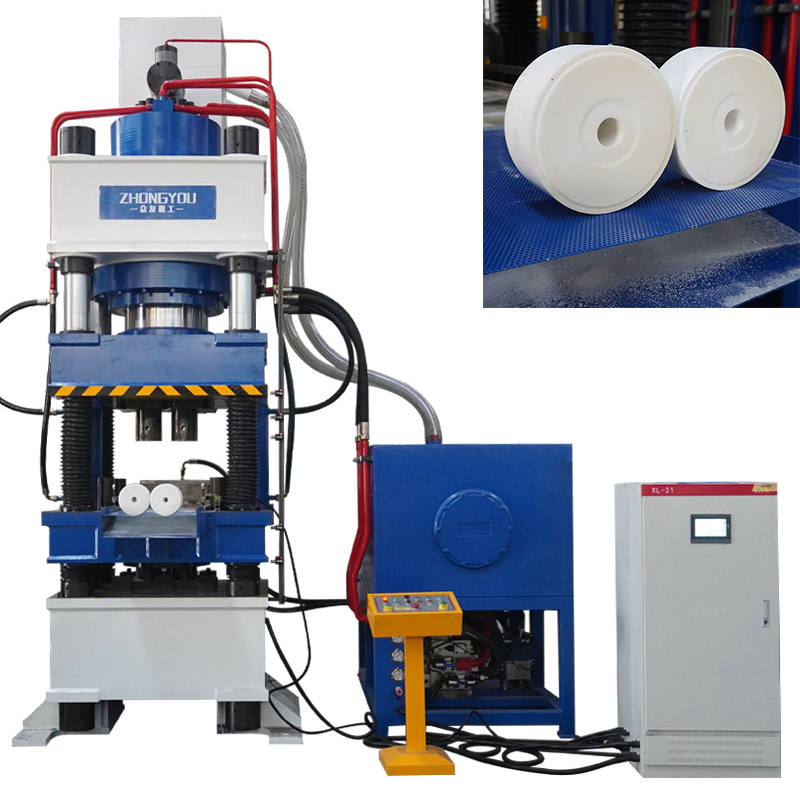

Lick Brick Machine One Out One Pull Salt Brick Machine

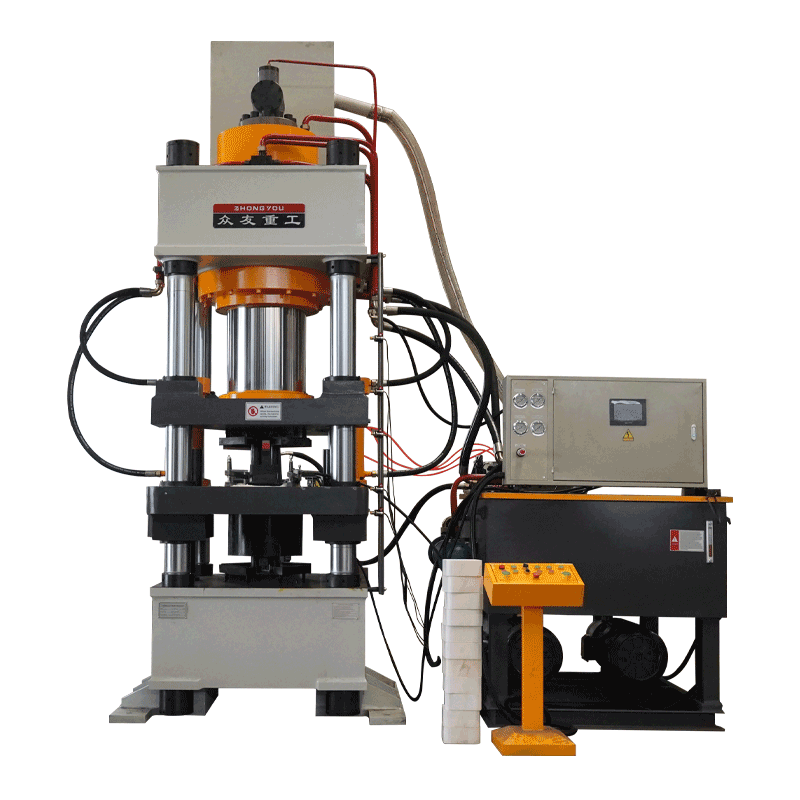

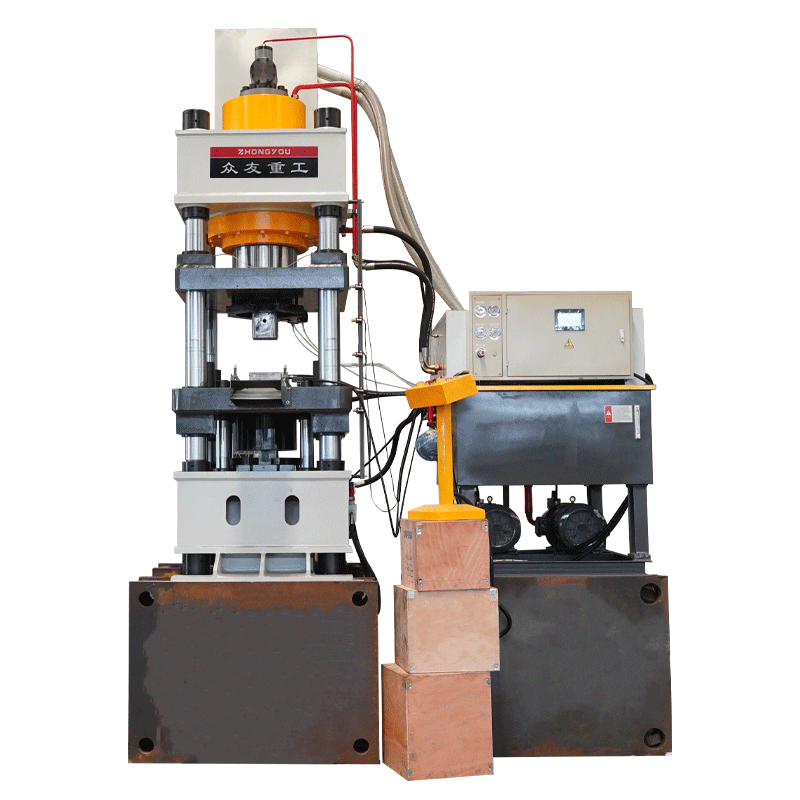

Cattle and Sheep Lick Brick Machine Hydraulic Press is a hydraulic moulding machine specially designed for producing cattle and sheep lick bricks (a kind of mineral supplement feed for livestock licking).Its core function is to apply high pressure through the hydraulic system to press the mixed mineral raw materials (such as salt, calcium, phosphorus, trace elements, etc.) into lick bricks of specific shape, density and hardness to meet the needs of nutritional supplements in cattle and sheep breeding.

Description

Cattle and Sheep Lick Brick Machine Hydraulic Press is a hydraulic moulding machine specially designed for producing cattle and sheep lick bricks (a kind of mineral supplement feed for livestock licking).Its core function is to apply high pressure through the hydraulic system to press the mixed mineral raw materials (such as salt, calcium, phosphorus, trace elements, etc.) into lick bricks of specific shape, density and hardness to meet the needs of nutritional supplements in cattle and sheep breeding.

Core features

High-pressure moulding, controllable density: the pressure of the hydraulic system is stable, and can be adjusted according to the raw material formula (e.g. raw materials with high calcium content need higher pressure to prevent loosening), to ensure even density of lick bricks (to avoid transporting broken).

Multi-specification: By replacing the moulds (round, square, diamond and other shapes, size range 100mm×100mm~1000mm×600mm), different specifications of licking bricks can be produced (to meet the different needs of calves, fattening cows, lactating cows, sheep, etc.).(to meet the different needs of calves, fattening cows, lactating cows, sheep, etc.).

Strong corrosion resistance: the moulds are made of stainless steel or plated with hard chrome, and the hydraulic system fluid is made of anti-abrasive hydraulic oil, which can adapt to the corrosion of salts in the raw materials (prolonging the life of the equipment).

High degree of automation: optional automatic loading, weighing, dust removal system, reducing manual intervention (only 1~2 people need to operate in a single shift), and improving production efficiency (single mould cycle 50~120 seconds, daily output 5~20 tons).

Low energy consumption: the hydraulic system adopts variable pump + servo control technology, which consumes electricity only when it is pressurised and automatically reduces the frequency when it is empty, so the energy-saving effect is remarkable.

During the pressing process, the hydraulic system drives the press head to move downward to press the salt material inside the mould, and after the pressing is completed, it adopts the downward pulling type mould releasing method to make the salt bricks come out from the mould smoothly.This pull-down mould release design has strong power and good stability, which helps to improve production efficiency and product quality.

Modern salt brick machines are usually equipped with automatic fabric, automatic pressing, automatic mould releasing, automatic block pushing and other functions, without the need for manual operation, to achieve a high degree of automation.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

Detailed Parameters

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |