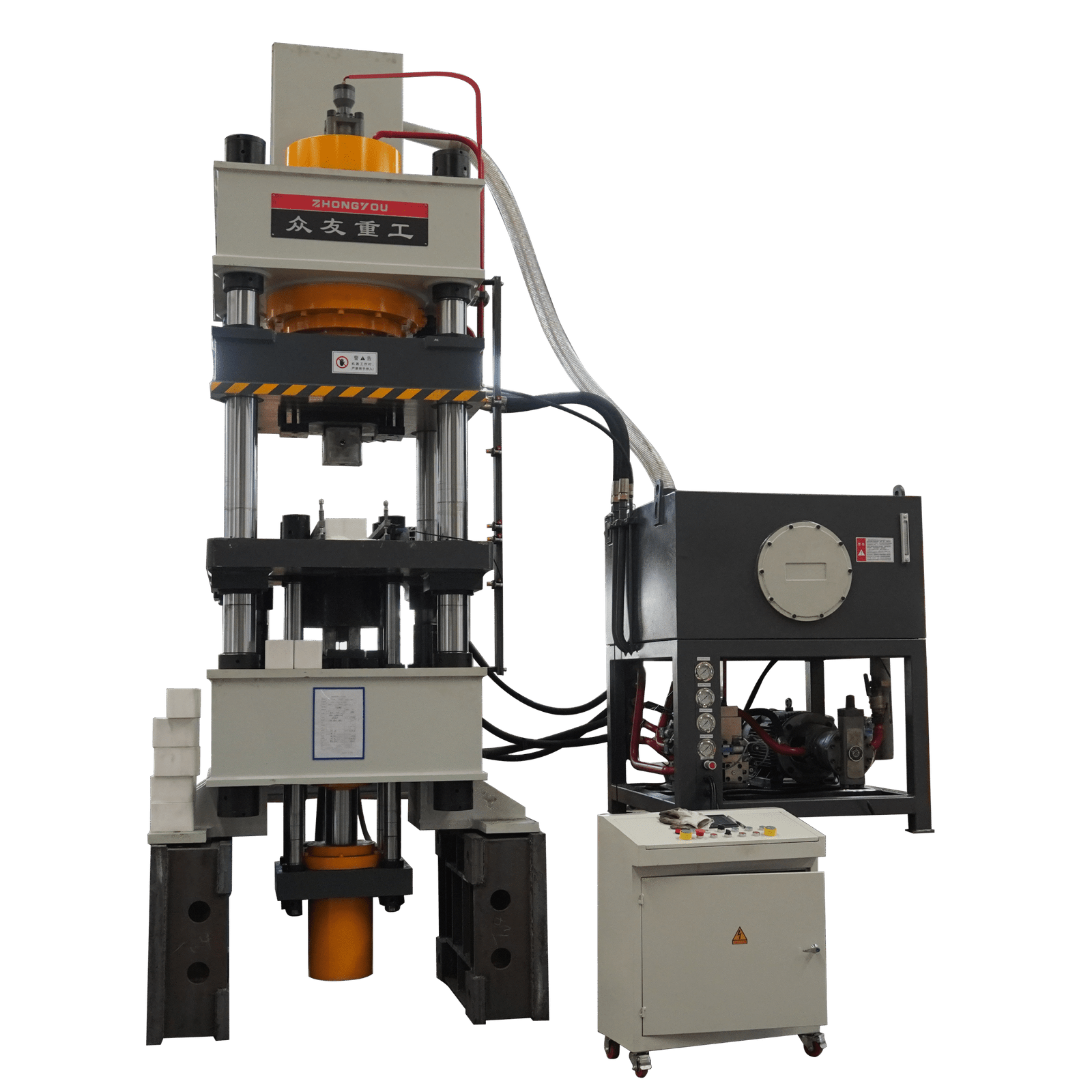

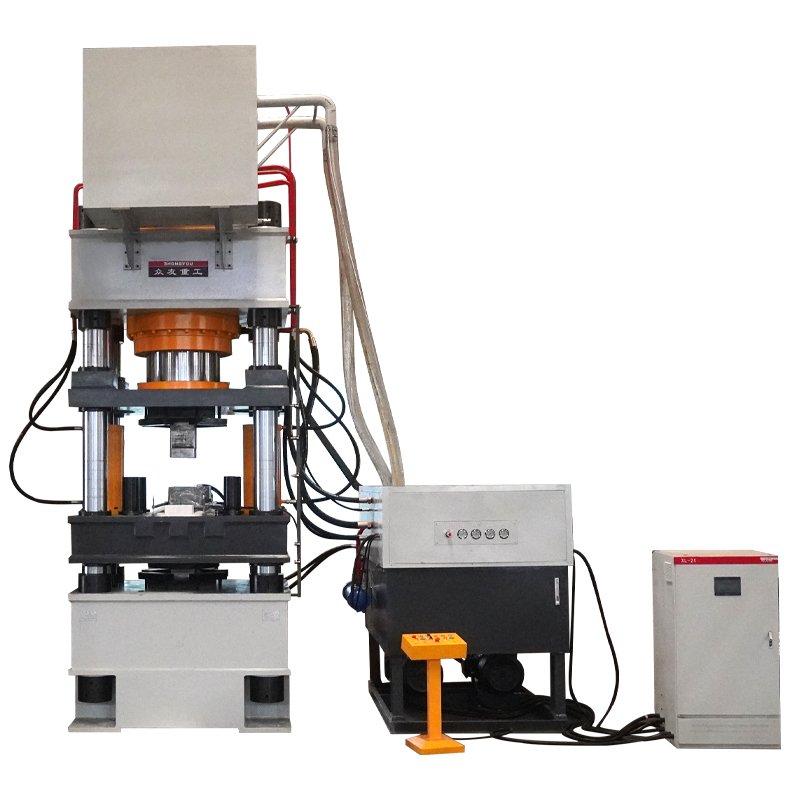

630-Ton Cattle and Sheep Lick Block Production Line Hydraulic press

The 630-ton salt block production line hydraulic press is a fully automatic powder forming hydraulic press specifically designed for the livestock industry. It features high efficiency, stability, and flexibility, making it suitable for the compression molding of livestock salt products such as cattle and sheep lick blocks.

Description

The 630-ton salt block production line hydraulic press is a fully automatic powder forming hydraulic press specifically designed for the livestock industry. It features high efficiency, stability, and flexibility, making it suitable for the compression molding of livestock salt products such as cattle and sheep lick blocks.

Core Equipment for the Livestock Industry

Primarily used for pressing cattle lick blocks, sheep lick blocks, nutritional lick blocks, mineral lick blocks, etc., providing cattle and sheep with trace elements such as calcium, phosphorus, iodine, copper, zinc, iron, and selenium to promote healthy growth.

Production Efficiency and Quality Advantages

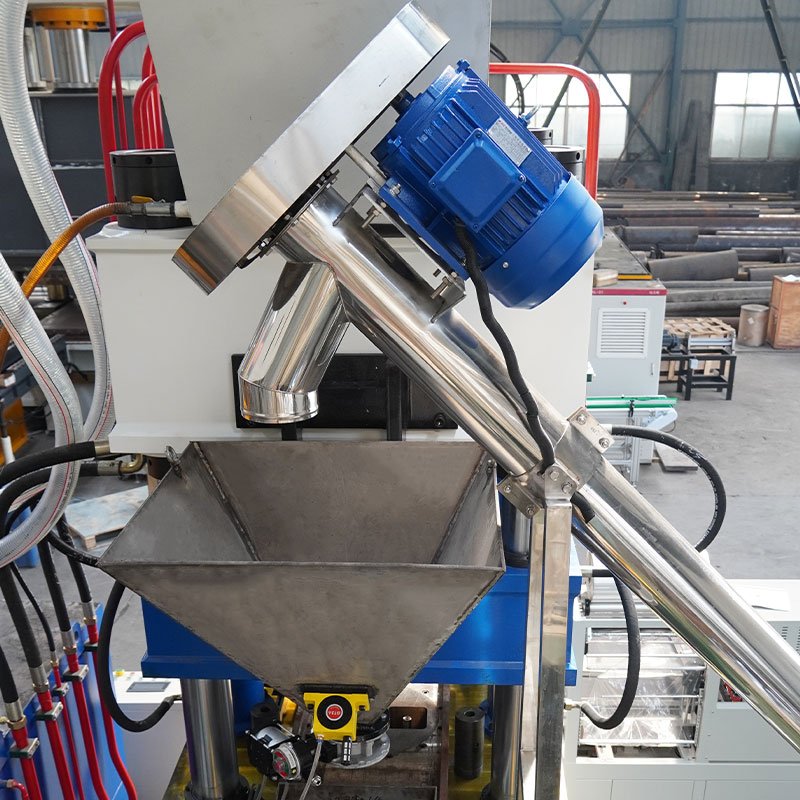

High-Efficiency Production: Each unit can operate independently or integrate into automated production lines (including mixers, material lifters, storage silos, automatic sealing/cutting machines, conveyor belts, etc.), enabling rapid, hygienic, and efficient manufacturing.

Superior Forming Results: Produces dense, durable salt blocks with consistent height and uniform appearance, ensuring strong market demand.

Energy-Efficient and Eco-Friendly: Utilizes advanced hydraulic transmission technology to reduce energy consumption and minimize noise pollution.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

Detailed Parameters

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |