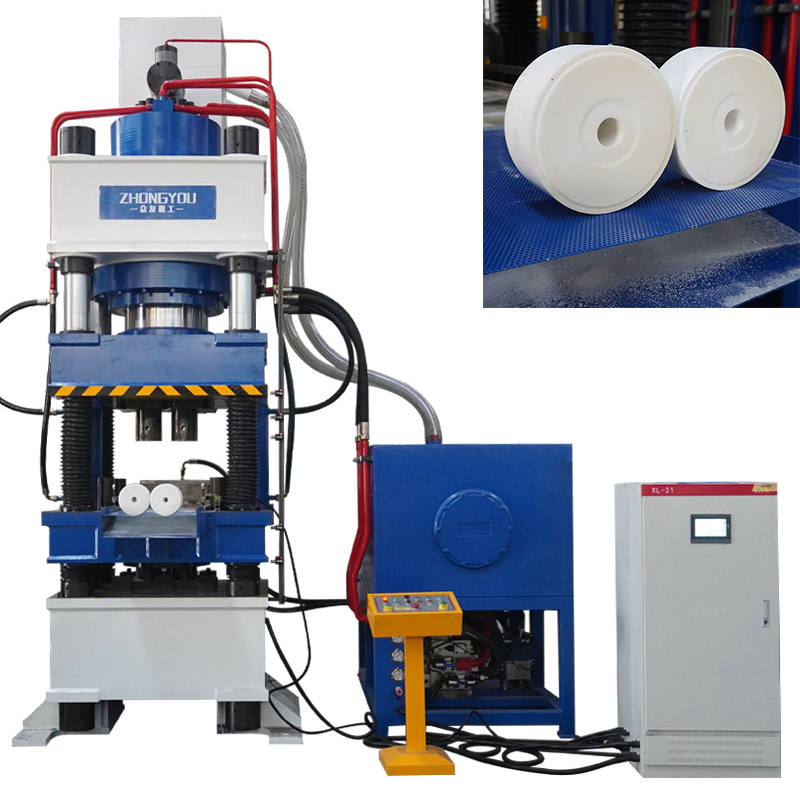

500-Ton Cattle Lick Block Production Line

The core of this production line is a hydraulic press operating at 500 tons of pressure, which compresses salt powder (typically livestock salt) into high-density salt bricks (lick blocks) for ruminants such as cattle and sheep to lick.

Description

The core of this production line utilizes a 500-ton hydraulic press to compress salt powder (typically livestock salt) into high-density salt bricks (lick blocks) for grazing animals like cattle and sheep to lick.

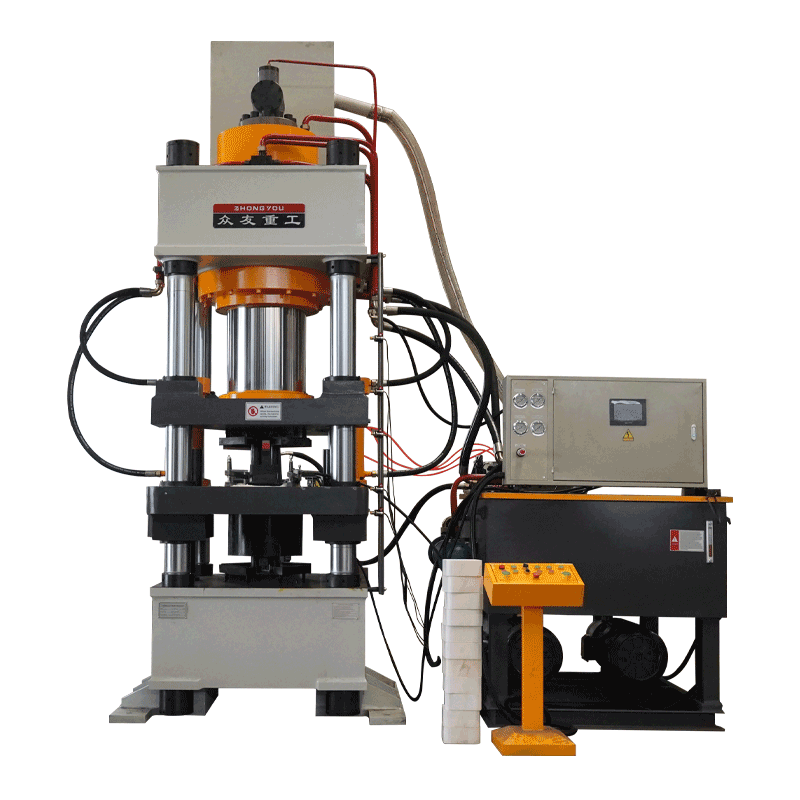

Main Machine Structure

Four-beam, four-column design: Features a high-rigidity frame to ensure structural stability during compression, minimize deformation, and enhance product precision.

Core Components: Includes upper and lower molds, pressing mechanism, hydraulic cylinders, etc. The hydraulic system drives the molds to compress and shape the salt material.

Drive System: An electric motor powers the hydraulic pump, transmitting pressure through hydraulic lines to the cylinders. This drives the molds’ vertical movement to complete the pressing action.

Livestock Farming

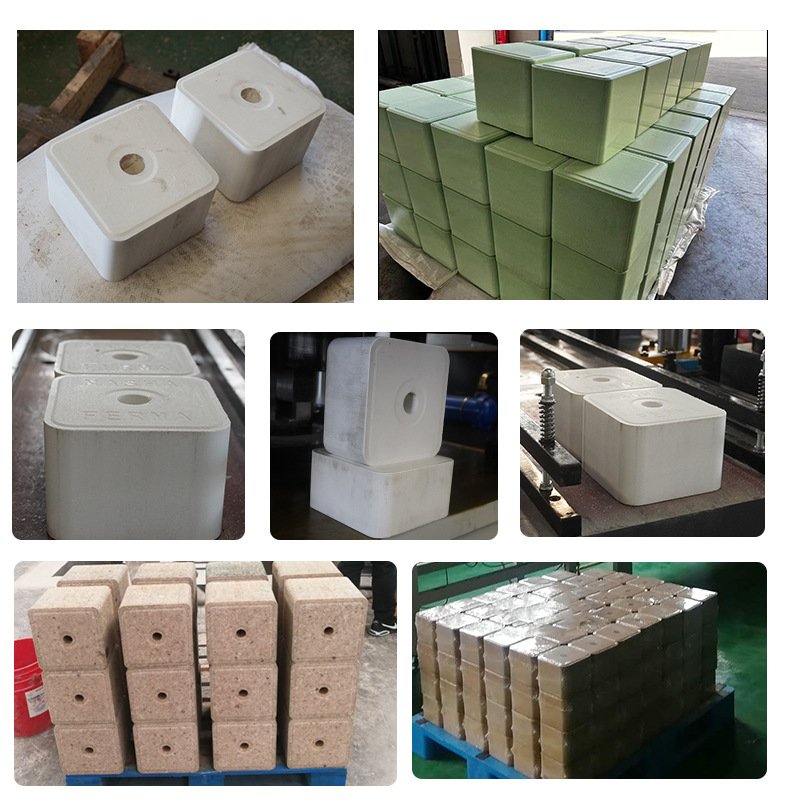

Nutritional Supplementation: Compresses salt, minerals, and trace elements (e.g., calcium, phosphorus, iron, zinc) into scientifically formulated blocks for cattle and sheep to lick. Maintains electrolyte balance while promoting growth, development, and reproduction.

Industrial Applications

Powder Forming: Beyond salt bricks, also forms materials like fish bait, nutrient pellets, and metal powder briquettes, expanding equipment versatility.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

Detailed Parameters

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |