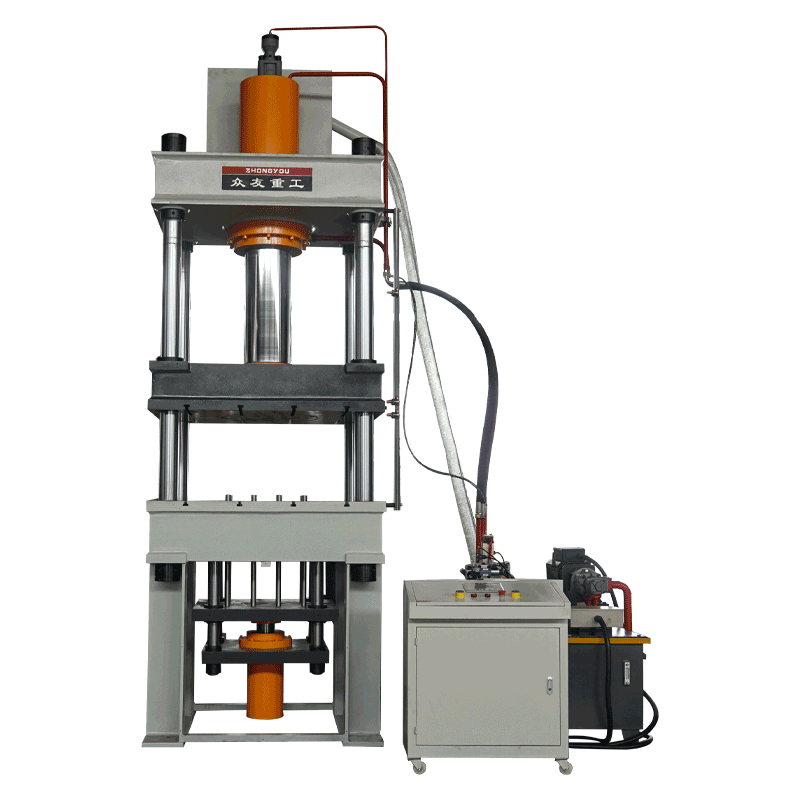

Three beams and four kinds of stretching machine

Three-beam four-column metal stretching hydraulic press is a kind of hydraulic equipment widely used in the process of stretch forming, flanging, bending and stamping of sheet metal parts.

Description

Three-beam four-column metal stretching hydraulic press is a kind of hydraulic equipment widely used in the process of stretch forming, flanging, bending and stamping of sheet metal parts.

Performance Advantages

Adjustable pressure: through the control system, users can adjust the pressure of hydraulic oil as needed, thus controlling the strength and precision of pressing.

High precision and stability: each machine is equipped with infrared sensing safety grating, which ensures that the repeated precision level of the machine can reach (+0.03mm) and the working pressure deviation (+1%).The whole mechanical frame structure is solid, impact resistance and strong resistance to side pressure working ability, smooth and high precision durable.

High efficiency and energy saving: hydraulic transmission system with low calorific value, the oil tank can be smaller than the traditional type of four-column hydraulic press, and the time of oil change can be increased.At the same time, the hydraulic press and electronics manipulation selection of intelligent environmental protection and energy saving system software, environmental protection and energy saving 50% ~ 70%.

High degree of automation: to promote the three-beam four-column hydraulic press working pressure, rate and parts are selected closed-loop control computer control, high level of automation technology, good precision, wide range of applications.

Low noise: to promote the hydraulic pump is generally used to gear oil pump, compared with the traditional four-column hydraulic press selection of variable piston pump, the noise is lower.

Equipment failure rate is low: intelligent automatic control system makes the temperature is not easy to quickly rise, the oil pipeline system software without negative pressure, greatly reducing the common failures, increasing the use of the hydraulic system life.

Convenient maintenance: hydraulic transmission system greatly simplified, reducing the gear oil environmental pollution system on the hazards.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Detailed Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |