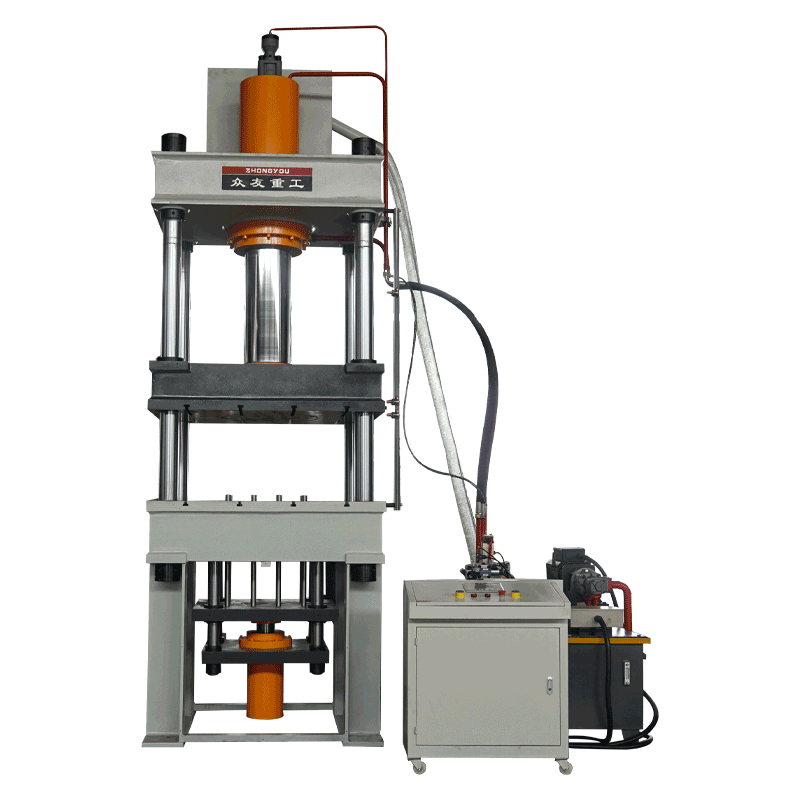

200 Ton Hydraulic Press Machine for Mental Deep Drawing

Sheet Metal Forming Hydraulic Press is a model of four columns hydraulic press machine, it can be divided in to two kinds of types according to the action movement, one is double action hydraulic press, the other one is single action hydraulic press.Metal stretching hydraulic press is a kind of hydraulic equipment used for metal plate stretch forming

.

Description

Metal stretching hydraulic press is a kind of hydraulic equipment used for metal plate stretch forming

Equipment structure and characteristics

1. three-beam and four-column structure: the machine body adopts three-beam and four-column design, which is economical and practical, with solid structure, optimised design of stress parts, beautiful appearance, high rigidity and durability.

2. Hydraulic control system: adopting cartridge valve integrated system, reducing leakage points, reliable action, long service life, small hydraulic shock, and improving production efficiency.

3. Operation mode: the equipment is equipped with button centralised control, which can realise manual, semi-automatic and automatic operation modes, easy to operate.

4. safety protection: the equipment is equipped with photoelectric protection device and emergency stop button to ensure the safety of personnel and equipment during operation.

5. Control system: PLC programming system is adopted to realise the free switching of automatic and semi-automatic operation modes, which is convenient for the maintenance of the equipment, and the operating speed and pressure of the main cylinder can be adjusted arbitrarily.

6. Multi-functionality: the equipment can realise two kinds of forming process: fixed pressure and fixed range, with the function of holding pressure and delaying time, and the working pressure and stroke can be adjusted within the specified range.

Application fields

1. metal sheet stretch forming: it is suitable for stretching water tank, stretching anchor tray, stretching stainless steel sink, stretching hardware, stretching automobile fittings, stretching head, deep stretching of workpiece, shallow stretching of workpiece, stretching of corrugated board, stretching of motor wind shield, stretching of metal sheet metal, etc.

2. Composite material moulding: it can be used for moulding of thermosetting and thermoplastic composite materials such as BMC, SMC, DMC, GNT, D-LFT, G-LFT, and so on.

3. Non-metallic material moulding: it is applicable to the hot press moulding process of non-metallic materials such as resin manhole cover, PMC, salt lick brick, bait block, environmental protection brick, etc.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Detailed Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |