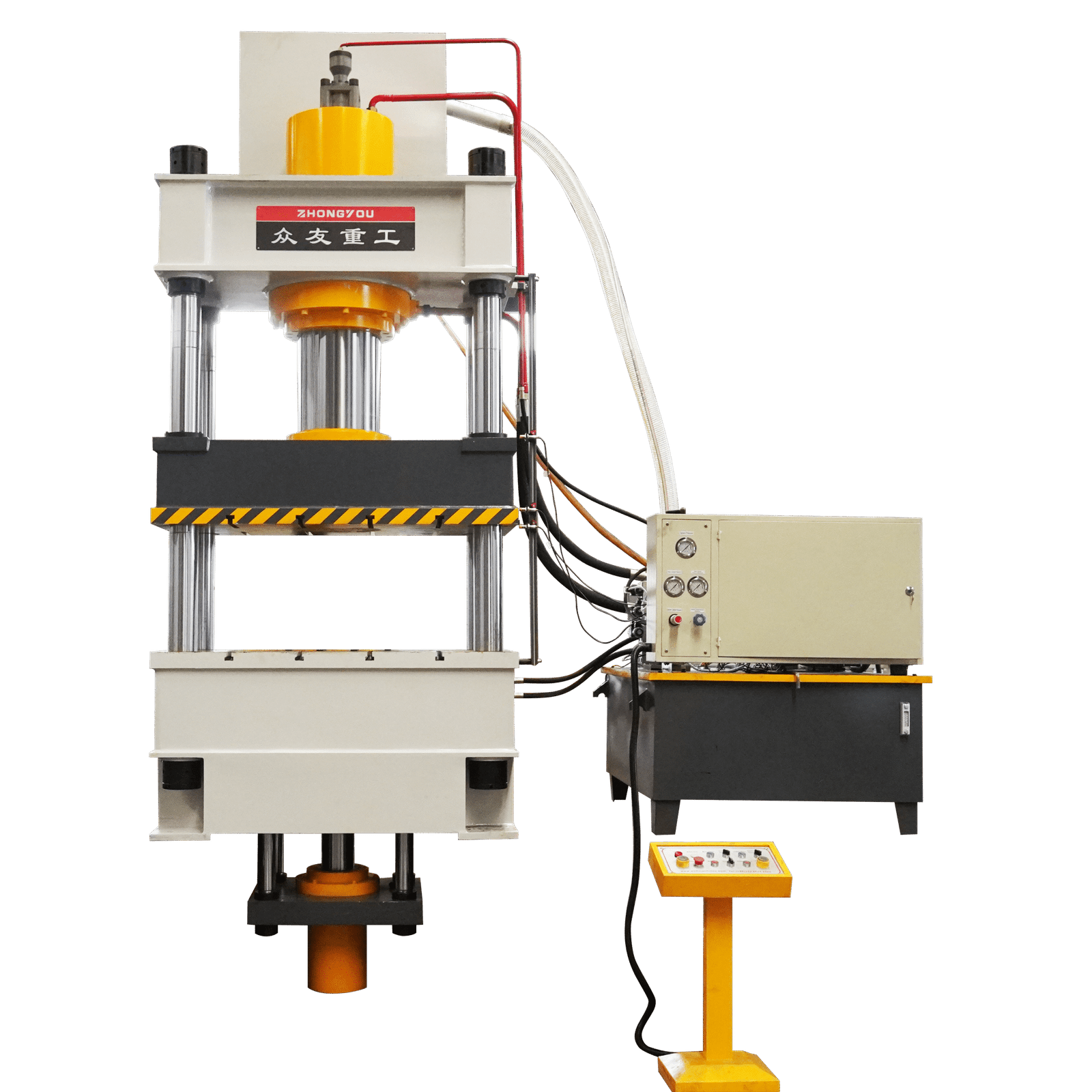

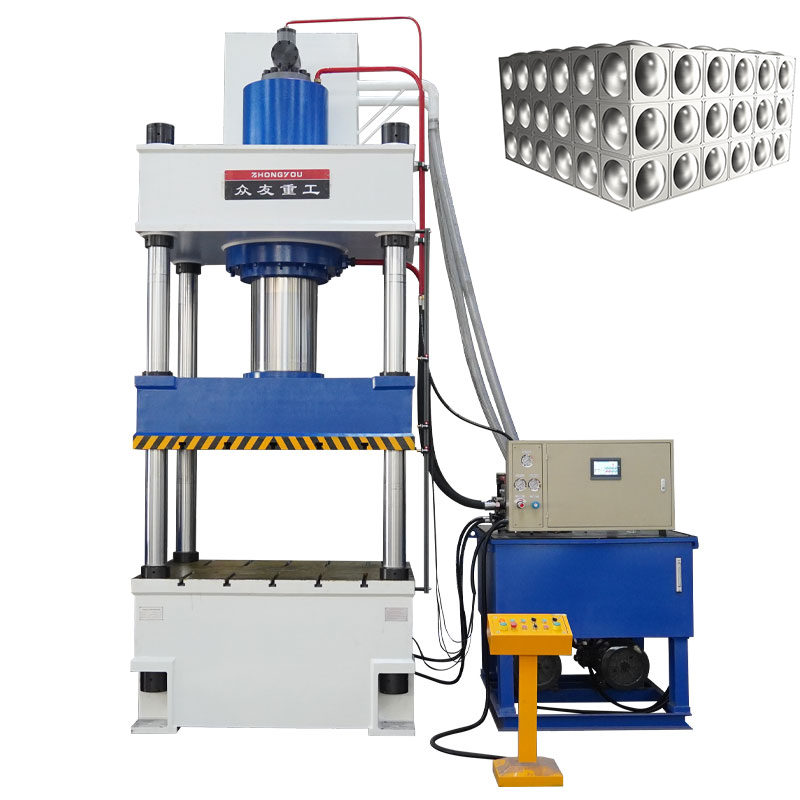

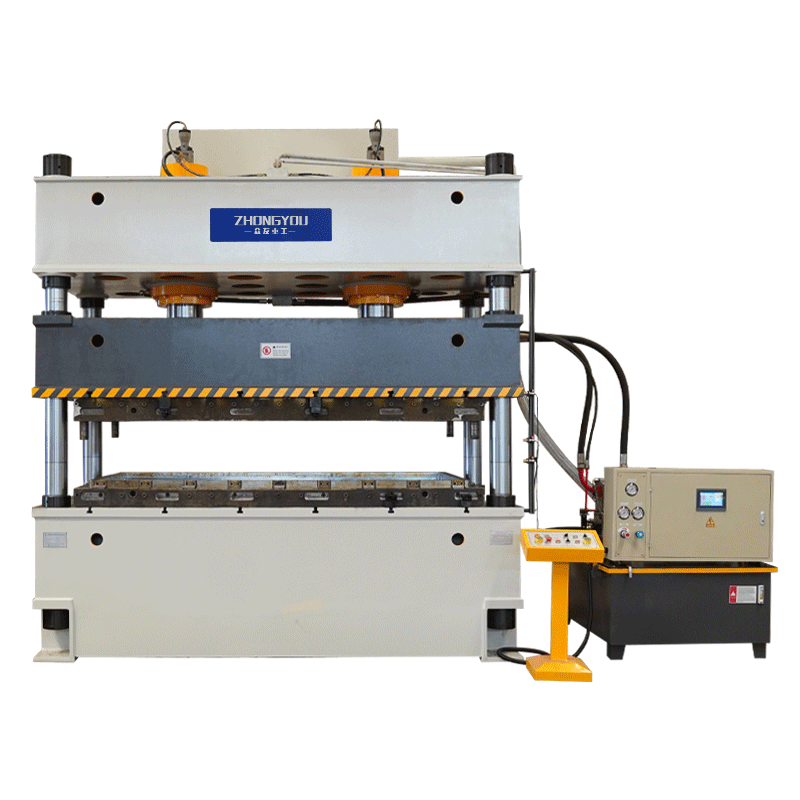

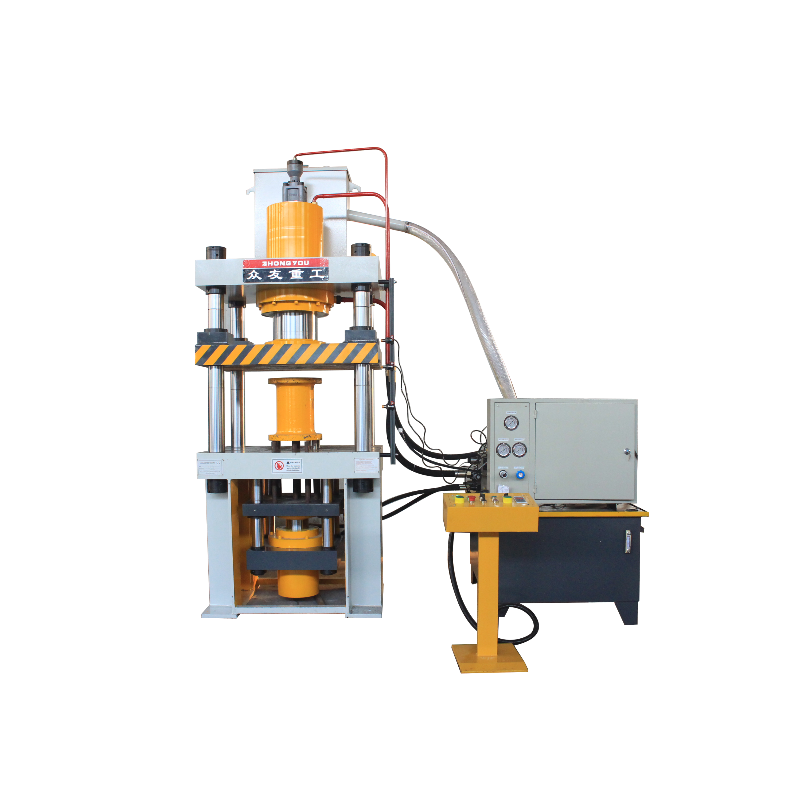

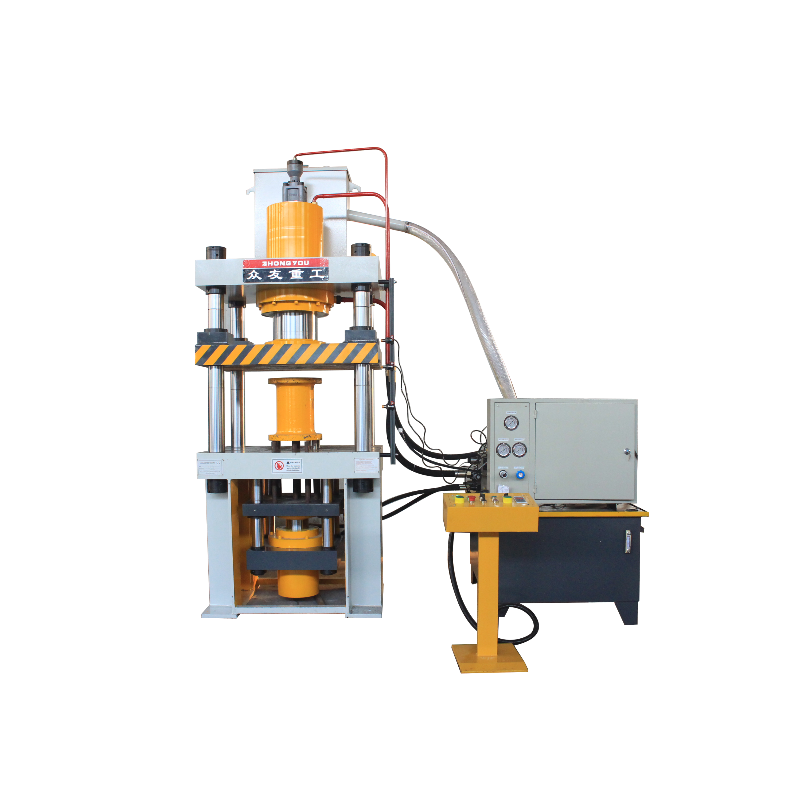

200Ton Hydraulic Press Machine for Metal Deep Drawing

200 ton hydraulic press sheet metal forming press machine structure is formed, and various parameters and table tops can be customized according to customer needs. The hydraulic control adopts a cartridge valve integrated system, which is durable and has a long service life.

Description

200 tons Four-Column Hydraulic Press is one of the new generations of plate process. Three-beam and four-pole structure design for large operating spaces – suitable for sheet metal forming, punching, bending, straightening, and multi-press assemblies to form an automatic production line.

The main components of the hydraulic press machine are:

- Main machine: It consists of a frame, a main hydraulic cylinder, a pusher hydraulic cylinder, a bottom plate hydraulic cylinder, a supporting mold frame, a mold, and a pressure.

- Hydraulic station: It consists of motor, hydraulic pump, pump protection device, control valve block, and piping system for continuous briquetting machine.

- Console: It consists of an electrical system and a PLC control system.

Metal sheet stretch forming: it is suitable for stretching water tank, stretching anchor tray, stretching stainless steel sink, stretching hardware, stretching auto parts, stretching head, deep stretching of workpiece, shallow stretching of workpiece, stretching of corrugated plate, stretching of motor air cover, stretching of metal sheet metal, etc.

Composite material moulding: It can be used for moulding of thermosetting and thermoplastic composite materials such as BMC, SMC, DMC, GNT, D-LFT, G-LFT, etc.

Non-metallic material moulding: it is applicable to the hot press moulding process of non-metallic materials such as resin manhole cover, PMC, salt lick brick, fish bait block, environmental protection brick, etc.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Detailed Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |