YM-200Ton forklift tyre press machine for solid tire changer

The tire press is a kind of tire disassembly equipment, which is used to disassemble the rim and tire with the retaining ring, and is mainly used for disassembly and assembly of various solid tires. When using, firstly select the tooling correctly, then place the wheel hub on the workbench, press the tool head to press the tire on the tire, press it into the wheel hub, and finally load the snap ring with the guide ring. Different types of tires and wheels require different tooling.

Description

YM-200Ton forklift tyre press machine for solid tire changer

The tire press is a kind of tire disassembly equipment, which is used to disassemble the rim and tire with the retaining ring, and is mainly used for disassembly and assembly of various solid tires. When using, firstly select the tooling correctly, then place the wheel hub on the workbench, press the tool head to press the tire on the tire, press it into the wheel hub, and finally load the snap ring with the guide ring. Different types of tires and wheels require different tooling.

Solid tires are tires that do not need to be inflated and do not need to be filled with liquid, sponge or other non-solid material, made entirely of rubber, with a certain hardness and elasticity, for carrying the vehicle load and walking tires.

It is a hydraulic machine customized by our company according to the characteristics of the tire industry. It is mainly used for the replacement and installation of solid tires to facilitate the tire manufacturers and distributors to disassemble and disassemble tires and improve work efficiency.

used disassembly changer solid forklift tire press machine packing:

1. inner layer is made of plastic film rust-proof packaging,

2. the embossing machine outer layer is reinforced by reinforcing the synthetic board

3. separate container can be used.

Port: qingdao

Views: 0

Compression molding process

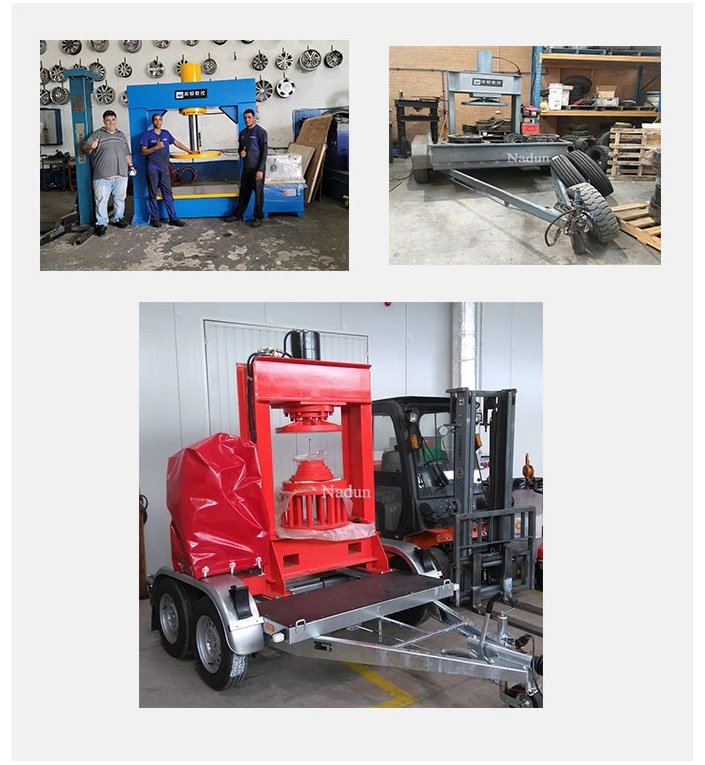

Customer Case

Technical Specifications

| Tonnage | Working Pressure | Cylinder Diameter/Rod Diameter | Effective Table Size | Opening Height | Stroke | Pressing Speed | Return Speed | Motor Power | Oil Pump Specification |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000×800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (fixed) |

| 120 | 31.5 | D220/d110 | 1000×800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (fixed) |

| 160 | 31.5 | D250/d150 | 1400×800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (fixed) |

| 200 | 31.5 | D290/d160 | 1500×800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (fixed) |

| 250 | 31.5 | D310/d180 | 1500×800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| 300 | 31.5 | D360/d220 | 1500×800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

Detailed Parameters

| Tonnage | Working Pressure | Cylinder Diameter/Rod Diameter | Effective Table Size | Opening Height | Stroke | Pressing Speed | Return Speed | Motor Power | Oil Pump Specification |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000×800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (fixed) |

| 120 | 31.5 | D220/d110 | 1000×800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (fixed) |

| 160 | 31.5 | D250/d150 | 1400×800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (fixed) |

| 200 | 31.5 | D290/d160 | 1500×800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (fixed) |

| 250 | 31.5 | D310/d180 | 1500×800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| 300 | 31.5 | D360/d220 | 1500×800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

Product Video