Wood chip tray forming equipment

Wood chip pallet molding equipment is used to mix wood chips (or straw, bamboo chips and other agricultural and forestry wastes) with adhesive, and then press and mold them into environmentally friendly pallets by physical or chemical methods.

Description

These pallets are characterized by low cost, degradability, resource recycling, etc. They are widely used in logistics, warehousing, food, chemical and other industries, and are ideal alternatives to traditional wooden/plastic pallets.We can produce an entire line of wood chip pallets.

Take the production of wood chip pallet by hot press molding method as an example, the typical flow is as follows:

Raw material pretreatment: wood chips → crushing → drying → screening (removing impurities) → magnetic separation (removing metals).

Mixing and blending: wood chips + adhesive + additives (waterproofing agent, flame retardant) → biaxial paddle mixer evenly mixed.

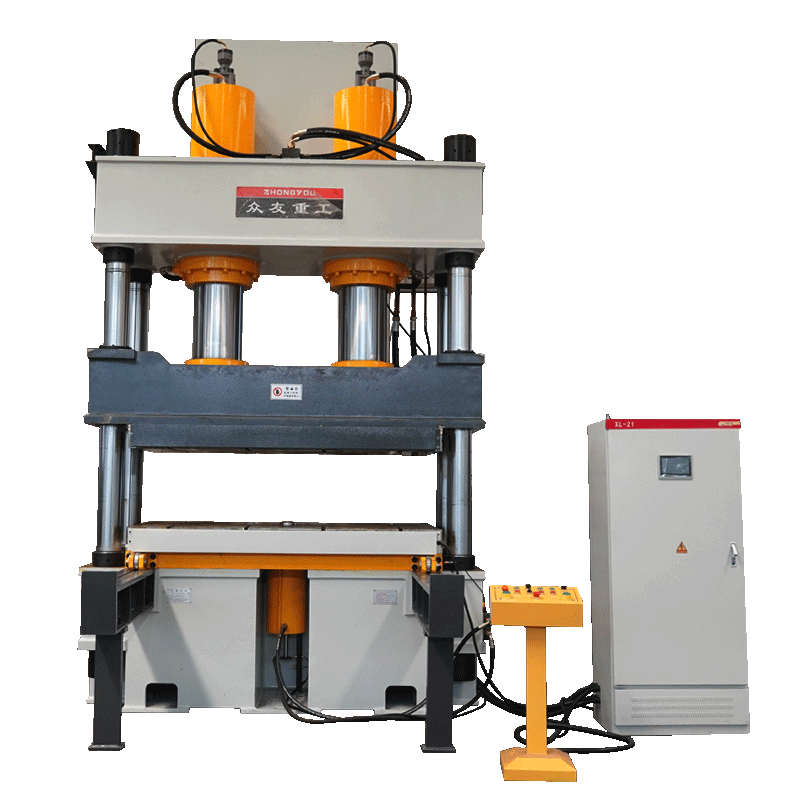

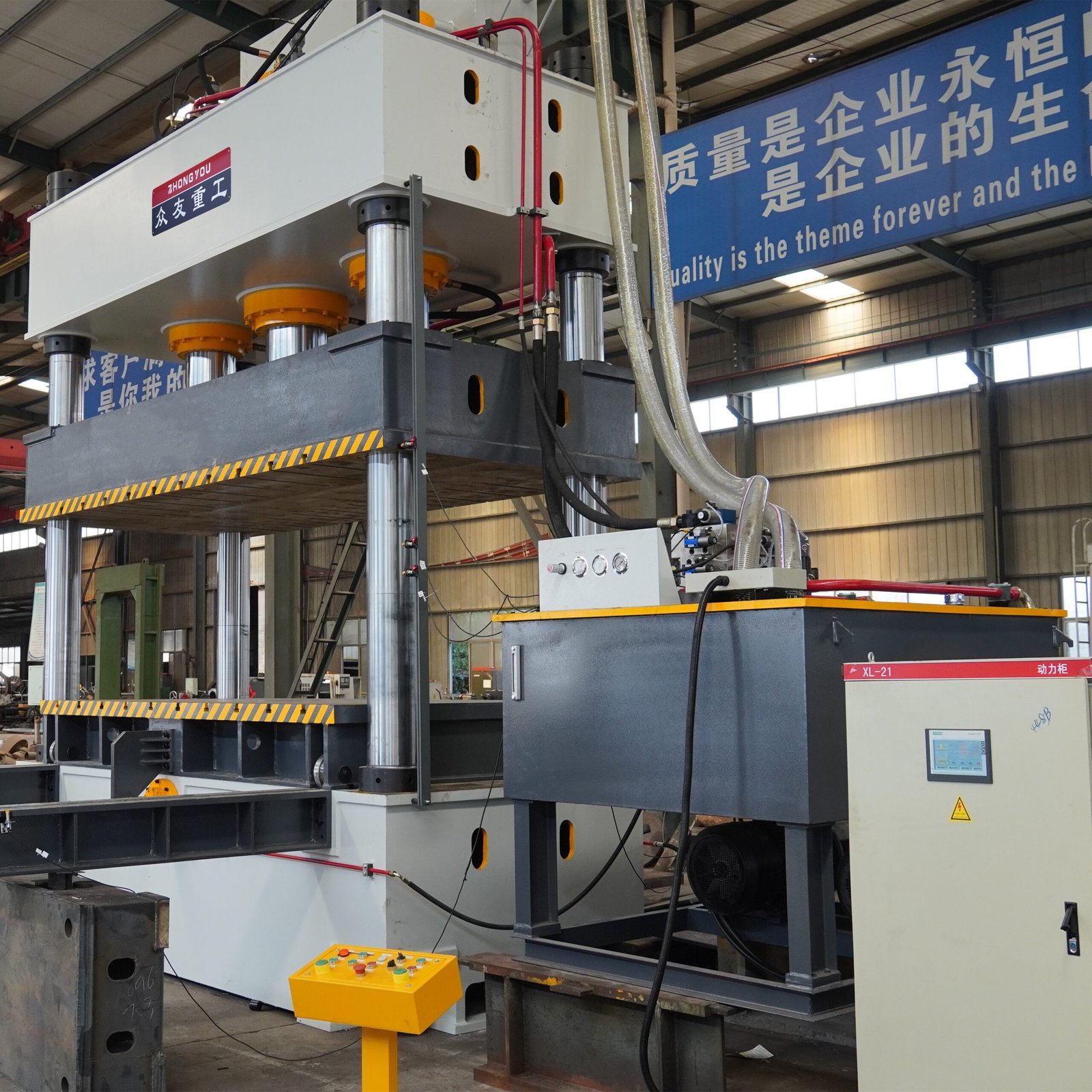

Molding: mixture → add to preheated mold → hydraulic press pressurization → holding pressure and curing → demolding (to get the first embryo pallet).

Post-processing of the first embryo pallet→cutting the edge)→inspection (size, load-bearing, appearance)→packaging→warehousing.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Name | Unit | YQ32-400 | YQ32-500 | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective Area of Workbench | mm | 1250×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 150 | 100 | 180 | 180 | 190 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 7-18 | 10-18 | 6-15 | 6-14 |

| Return Speed | mm/s | 100 | 180 | 200 | 90 | 220 | 200 | 220 |

| Ejecting Force | kN | 630 | 1000 | 1000 | 400 | 1000 | 1000 | 1600 |

| Maximum Ejecting Stroke | mm | 300 | 300 | 300 | 200 | 300 | 300 | 300 |

Detailed Parameters

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Name | Unit | YQ32-400 | YQ32-500 | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective Area of Workbench | mm | 1250×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 150 | 100 | 180 | 180 | 190 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 7-18 | 10-18 | 6-15 | 6-14 |

| Return Speed | mm/s | 100 | 180 | 200 | 90 | 220 | 200 | 220 |

| Ejecting Force | kN | 630 | 1000 | 1000 | 400 | 1000 | 1000 | 1600 |

| Maximum Ejecting Stroke | mm | 300 | 300 | 300 | 200 | 300 | 300 | 300 |