Mobile Tire Press for Engineering Vehicle Tire Changing

TheThe 100 ton mobile tire press belongs to hydraulic tire changer, designed for solid tires of forklift, flatbed trailer, engineering truck, etc. The 100 ton pressure is provided by the hydraulic system to realize the rapid separation of tires and rims.

100 ton mobile tire press belongs to hydraulic tire changer, designed for solid tires of forklift, flatbed trailer, engineering truck, etc. The 100 ton pressure is provided by the hydraulic system to realize the rapid separation of tires and rims.

Description

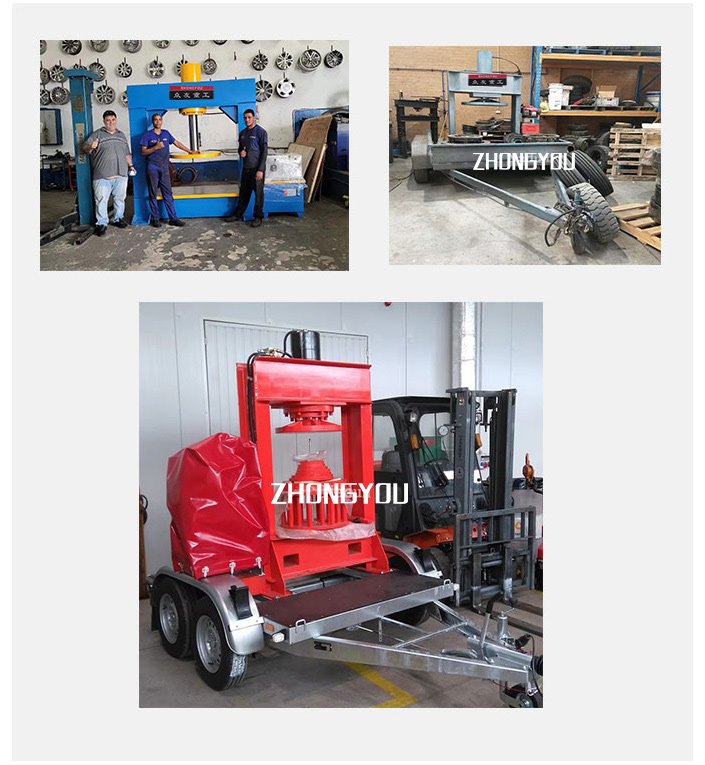

The 100-ton mobile tire press is a medium-sized movable hydraulic molding machine, mainly designed for medium-sized tires (such as truck tires, construction machinery tires, agricultural tires, etc.) repair, retreading, or small vulcanization molding needs.Its core feature is the moderate tonnage of “100 tons nominal pressure”, which can meet the processing needs of most medium-sized tires, while maintaining good mobility and flexibility for on-site work, mobile service or small-scale production workshops.

Application Scenario:

Forklift tire removal

Key requirements: high pressure, fast return, mold adaptability (covering 3T forklift front and rear tire specifications).

Engineering vehicle tire repair

Key requirements: ultra-high pressure, large table, anti-tipping design (gantry structure stability is better than mobile).

Field emergency repair

Key requirements: portability, rapid deployment, resistance to harsh environments (e.g., dustproof and waterproof design).

Views: 0

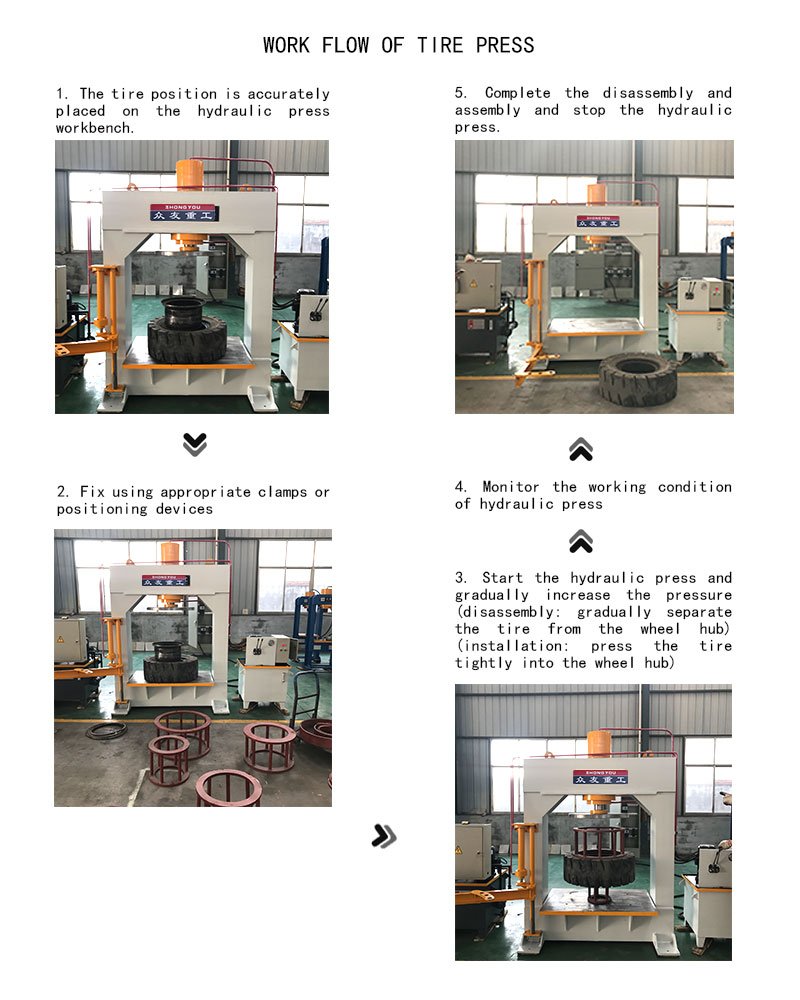

Compression molding process

Customer Case

Technical Specifications

| Tonnage | Working Pressure | Cylinder Diameter/Rod Diameter | Effective Table Size | Opening Height | Stroke | Pressing Speed | Return Speed | Motor Power | Oil Pump Specification |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000×800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (fixed) |

| 120 | 31.5 | D220/d110 | 1000×800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (fixed) |

| 160 | 31.5 | D250/d150 | 1400×800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (fixed) |

| 200 | 31.5 | D290/d160 | 1500×800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (fixed) |

| 250 | 31.5 | D310/d180 | 1500×800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| 300 | 31.5 | D360/d220 | 1500×800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

Detailed Parameters

| Tonnage | Working Pressure | Cylinder Diameter/Rod Diameter | Effective Table Size | Opening Height | Stroke | Pressing Speed | Return Speed | Motor Power | Oil Pump Specification |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000×800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (fixed) |

| 120 | 31.5 | D220/d110 | 1000×800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (fixed) |

| 160 | 31.5 | D250/d150 | 1400×800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (fixed) |

| 200 | 31.5 | D290/d160 | 1500×800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (fixed) |

| 250 | 31.5 | D310/d180 | 1500×800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| 300 | 31.5 | D360/d220 | 1500×800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5kw | 40McY (fixed) |