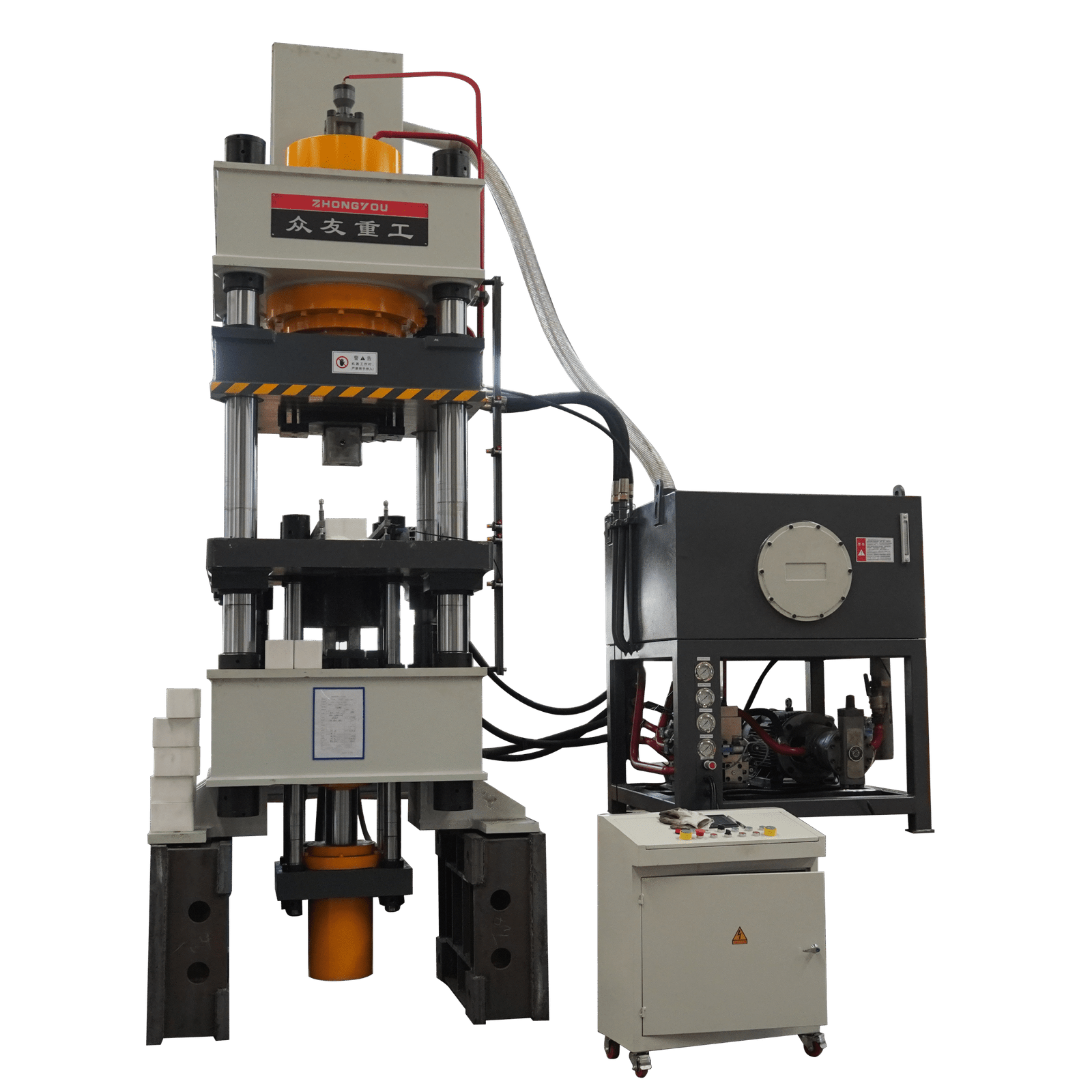

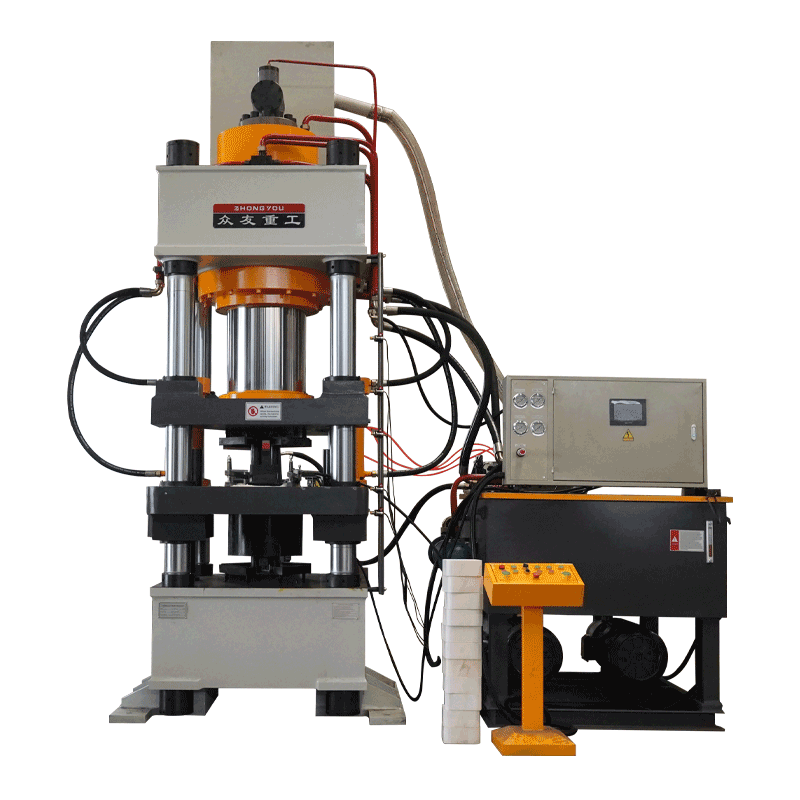

Metal powder molding hydraulic press

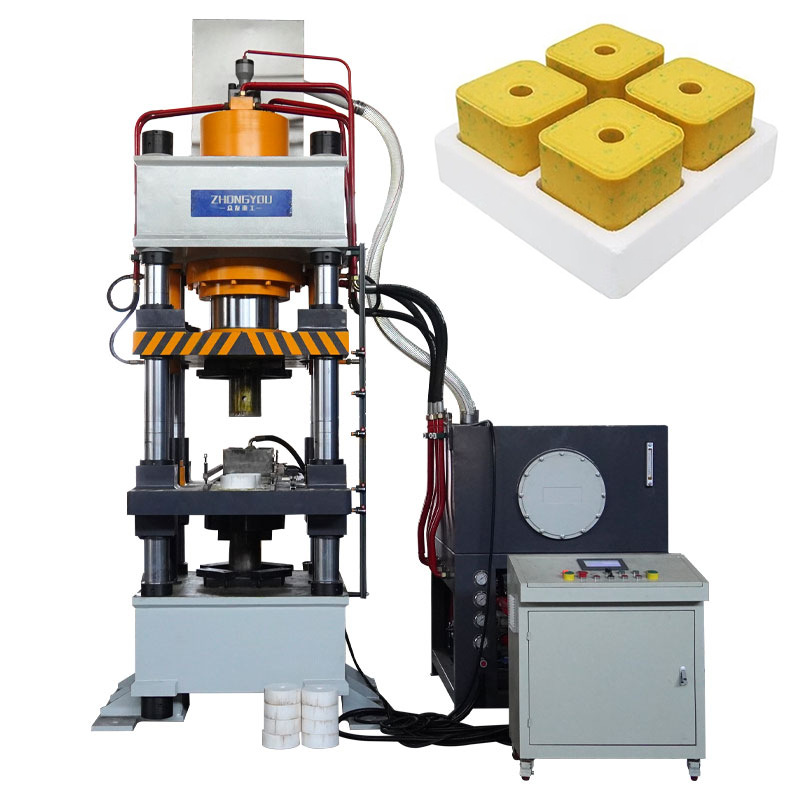

This is a customized 400 tons hydraulic press for zinc powder molding, which presses the metal powder into the required shape through the die, suitable for powder metallurgy, cemented carbide, magnetic materials, fine ceramics and other industries, especially suitable for pressing products with multiple steps and complex shapes.

Description

This is a customized 400 tons hydraulic press for zinc powder molding, which presses the metal powder into the required shape through the die, suitable for powder metallurgy, cemented carbide, magnetic materials, fine ceramics and other industries, especially suitable for pressing products with multiple steps and complex shapes.

Fields of application

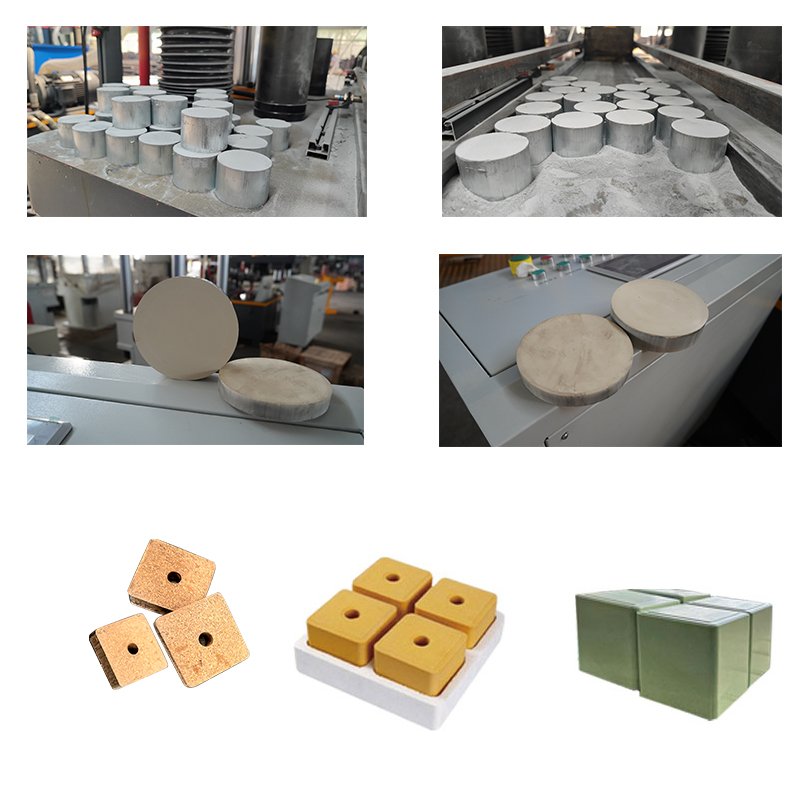

Powder metallurgy

Pressing iron and copper-based metal powders to produce gears, bearings, structural parts and other mechanical parts.

Iron-based powder metallurgy mechanical parts are the most widely used, accounting for the majority of powder metallurgy products.

Cemented Carbide and Magnetic Materials

Pressed carbide tools, molds and ferrite magnetic materials, rare earth permanent magnetic materials.

Fine ceramics and electronic ceramics

We press ceramic powders such as alumina and zirconia to produce electronic ceramic substrates and structural parts.

Other Fields

Precision molding of biomaterials, glass, alloys and other powders

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

Detailed Parameters

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |