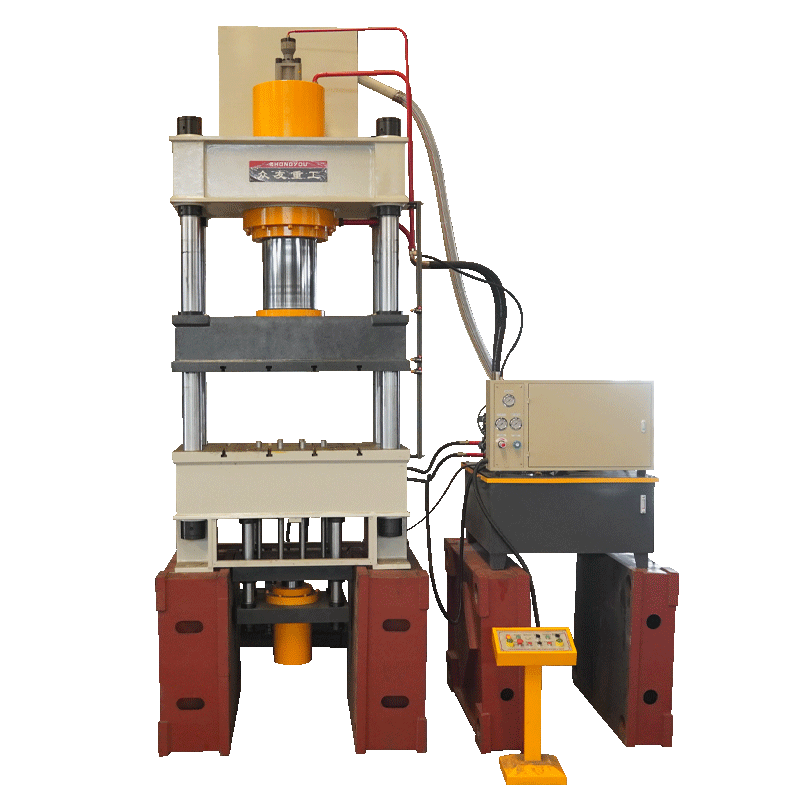

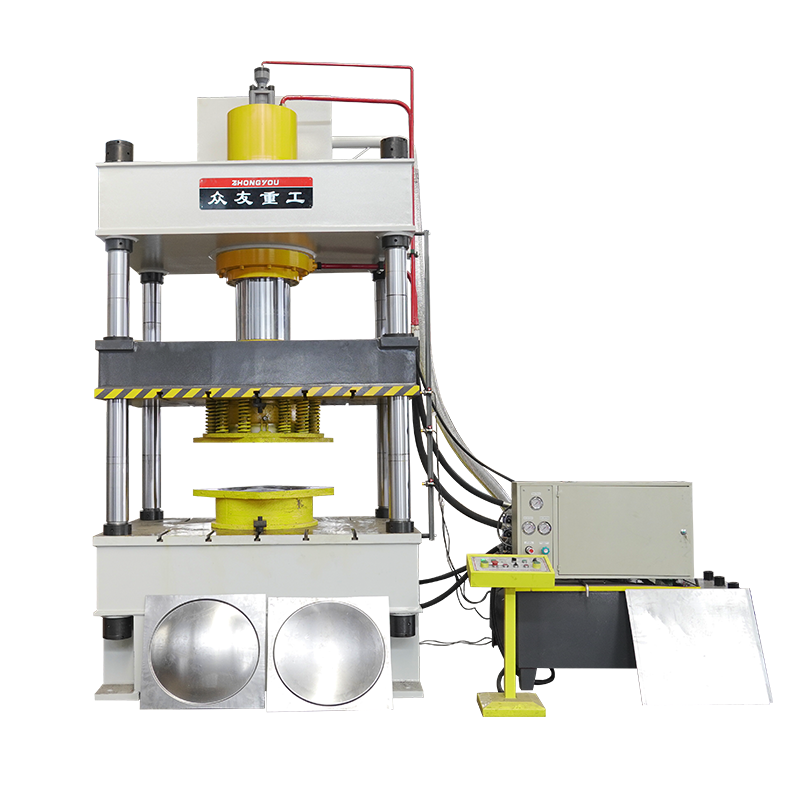

Metal deep drawing press 315 tons double action drawing machine

315-ton double-action stretching machine is a key equipment for cold press forming of sheet metal, mainly used for the manufacture of various types of tensile parts (such as automotive coverings, home appliance shells, industrial containers, etc.) By virtue of its double-action structure, high-precision control and energy-saving advantages, it has become the mainstream of sheet metal stretching and molding.

Description

Description: 315 tons double-action stretching machine is a kind of key equipment used for cold stamping and forming of metal sheets.

Advantages of double-action structure

Double-action stretching machine realizes the independent control of crimping and stretching through the cooperative work of master cylinder and crimping cylinder.The master cylinder provides the stretching force and the crimping cylinder regulates the crimping force, which effectively prevents the material from wrinkling or rupture, especially suitable for the production of complex shapes or high precision requirements of the tensile parts.

High precision and stability

Adopting four-column structure or C-frame design ensures the rigidity of the machine body. Equipped with high-precision guiding device and hydraulic servo system, it can realize micron-level position control and pressure stability to meet the demand of precision stretching.

Energy saving and efficiency

Some models adopt servo motor drive and variable pump technology to adjust the power output in real time according to the load, reducing energy consumption by 20%-30%.For example, the unit hourly power consumption of a model is reduced by 26.8% after the modification, while the noise of the pump station is reduced by 10dB.

Intelligent control

Equipped with PLC control system and human-machine interface (HMI), it supports multi-stage pressure, speed and holding time settings, and can store more than 200 sets of mold parameters, realizing one-key mold change and automated production.

Application Scenario

Stainless steel products

Sinks, tableware, kitchenware, decorative panels and other shallow or deep drawing molding, especially suitable for wall thickness of 0.5-2mm stainless steel sheet.

Aluminum products

Aluminum containers, radiators, automotive parts, etc., using double-action structure to control the crimping force and reduce the risk of material rupture.

Hardware and electronics industry

Clock shells, eyeglass frames, electronic component shells and other precision stretching parts, which need to be matched with high-precision molds and control systems.

Views: 0

Compression molding process

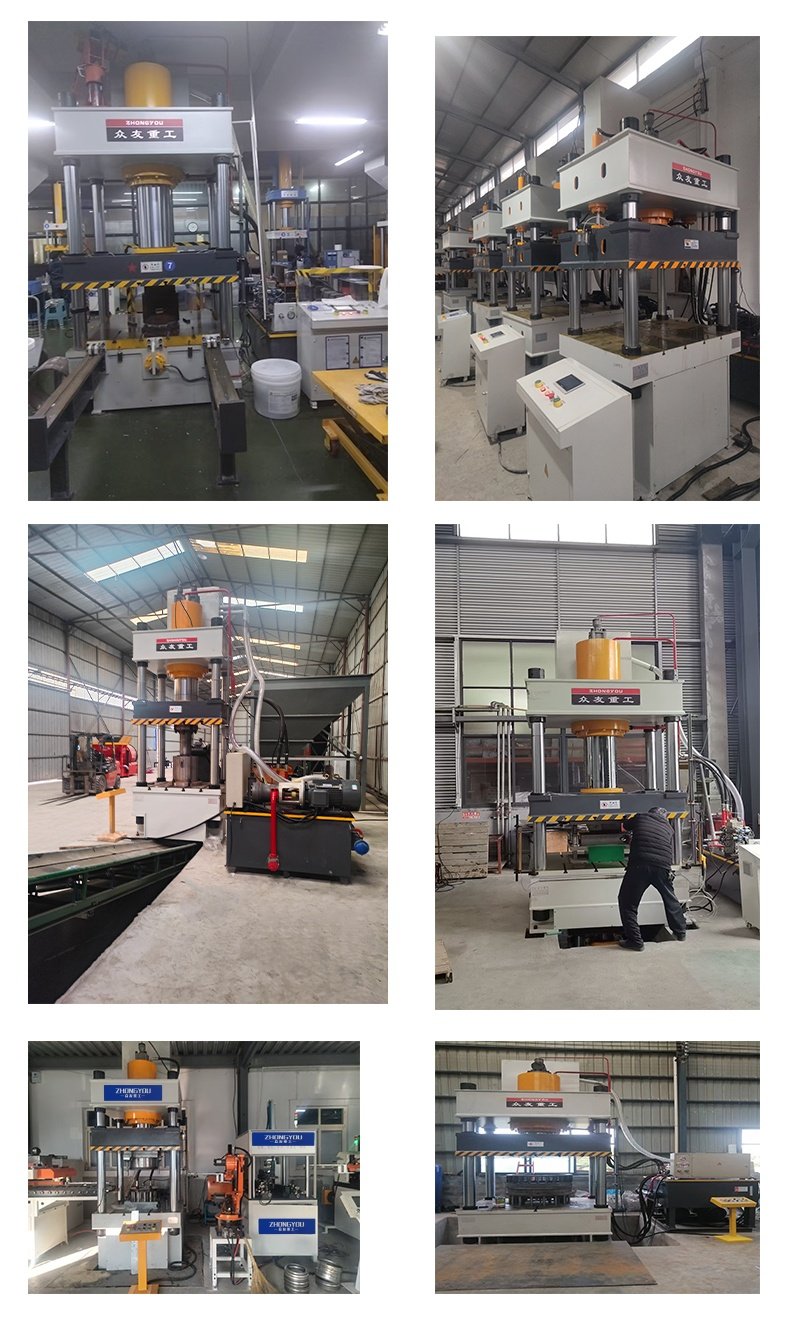

Customer Case

Technical Specifications

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Detailed Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |