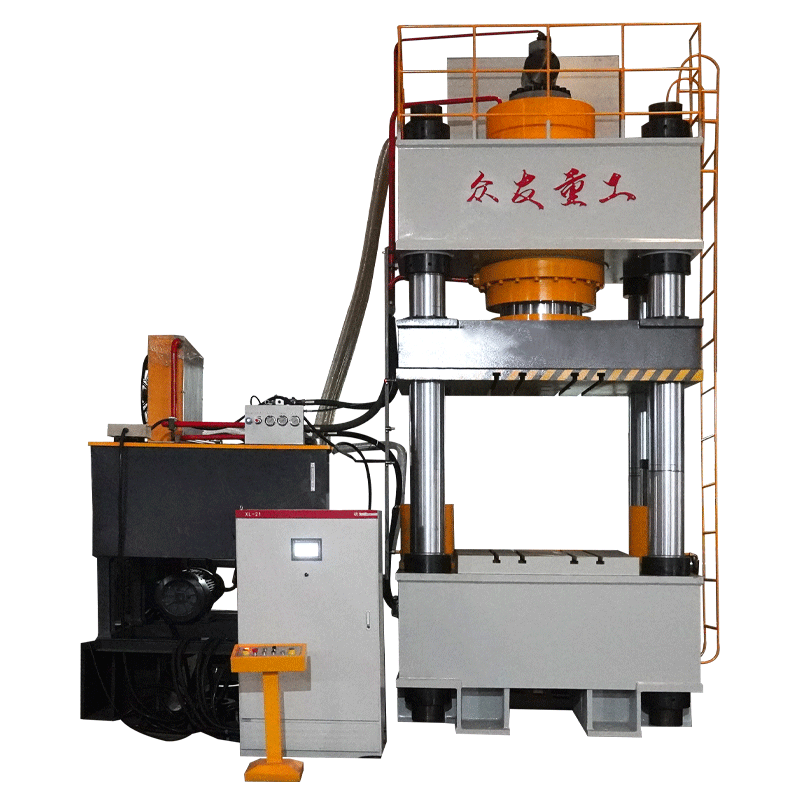

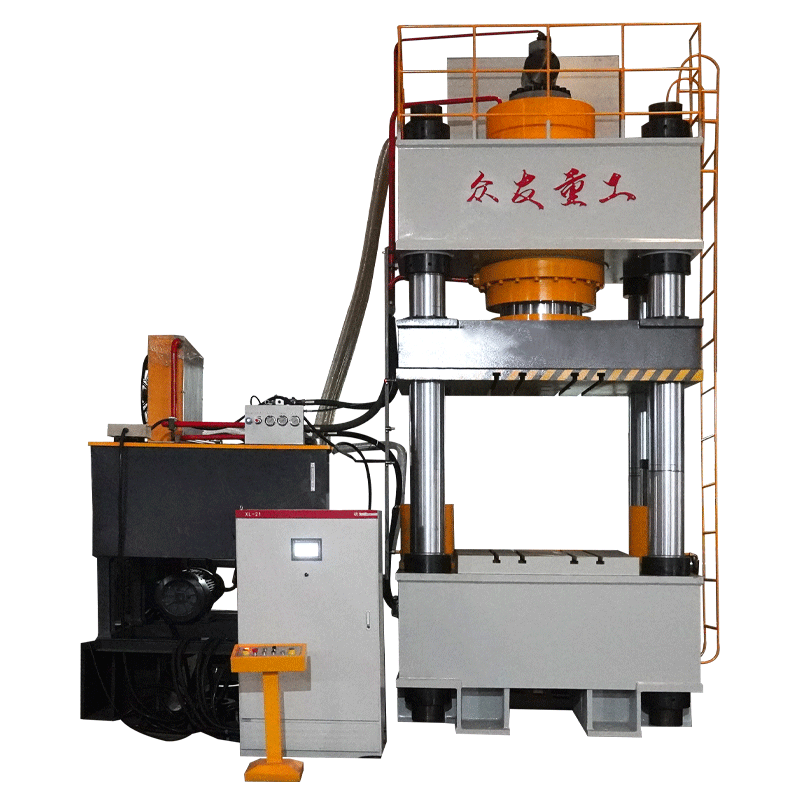

Industrial hydraulic press machine

1000ton four column press industrial hydraulic press machine。It is used for metal stamping, composite material hot pressing, powder molding, etc., with a wide range of application fields. This hydraulic press is equipped with a servo system, which is more energy-efficient, generates less noise, and has higher pressing accuracy. Through the touch screen, the operating parameters of the equipment and the pressing procedures can be adjusted, showing strong adaptability. The equipment is also installed with buffer cylinders to reduce noise and vibration during operation.

Description

1000ton four column press industrial hydraulic press machine。It is used for metal stamping, composite material hot pressing, powder molding, etc., with a wide range of application fields. This hydraulic press is equipped with a servo system, which is more energy-efficient, generates less noise, and has higher pressing accuracy. Through the touch screen, the operating parameters of the equipment and the pressing procedures can be adjusted, showing strong adaptability. The equipment is also installed with buffer cylinders to reduce noise and vibration during operation.

The three-beam, four-column hydraulic press is a large-scale forming machine integrating high precision, high efficiency and intelligence, designed for processes with stringent requirements on pressing accuracy and repetitive positioning (such as automotive coverings, precision mould stamping, new energy battery components, etc.).Its core feature is the adoption of three-beam and four-column frame structure to ensure stability, combined with servo motor drive.Combined with servo motor drive and closed-loop scale control, it achieves precise control of pressure and displacement.

Views: 0

Compression molding process

Customer Case

Technical Specifications

|

YQ32 Technical Parameters |

||||||||

| Unit | YQ32—63 | YQ32—100A | YQ32—100B | YQ32—200A | YQ32—200B | YQ32—315A | YQ32—315B | |

| Nominal force | KN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximun system pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Max.open height | mm | 700 | 800 | 900 | 900 | 1100 | 1000 | 1250 |

| Max Stroke of Slider | mm | 400 | 500 | 600 | 600 | 700 | 600 | 800 |

| Effective table size | mm | 610×500 | 630×550 | 750×700 | 800×800 | 1000×1000 | 800×800 | 1260×1160 |

| Down speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing speed | mm/s | 11~22 | 7~15 | 7~15 | 7~18 | 7~18 | 7~12 | 7~12 |

| Return speed | mm/s | 80 | 90 | 90 | 90 | 90 | 90 | 100 |

| Ejection cylinder force | KN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Stroke of ejection cylinder | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Unit | YQ32—400 | YQ32—500 | YQ32—630 | YQ32—800 | YQ32—1000 | YQ32—1250 | YQ32—1600 | |

| Nominal force | KN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximun system pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Max.open height | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Max Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective table size | mm | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Down speed | mm/s | 100 | 150 | 150 | 180 | 180 | 180 | 190 |

| Pressing speed | mm/s | 5~11 | 10~18 | 9~18 | 9~18 | 10~18 | 6~15 | 6~14 |

| Return speed | mm/s | 100 | 180 | 200 | 180 | 220 | 200 | 220 |

| Ejection cylinder force | KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Stroke of ejection cylinder | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

Detailed Parameters

|

YQ32 Technical Parameters |

||||||||

| Unit | YQ32—63 | YQ32—100A | YQ32—100B | YQ32—200A | YQ32—200B | YQ32—315A | YQ32—315B | |

| Nominal force | KN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximun system pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Max.open height | mm | 700 | 800 | 900 | 900 | 1100 | 1000 | 1250 |

| Max Stroke of Slider | mm | 400 | 500 | 600 | 600 | 700 | 600 | 800 |

| Effective table size | mm | 610×500 | 630×550 | 750×700 | 800×800 | 1000×1000 | 800×800 | 1260×1160 |

| Down speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing speed | mm/s | 11~22 | 7~15 | 7~15 | 7~18 | 7~18 | 7~12 | 7~12 |

| Return speed | mm/s | 80 | 90 | 90 | 90 | 90 | 90 | 100 |

| Ejection cylinder force | KN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Stroke of ejection cylinder | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Unit | YQ32—400 | YQ32—500 | YQ32—630 | YQ32—800 | YQ32—1000 | YQ32—1250 | YQ32—1600 | |

| Nominal force | KN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximun system pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Max.open height | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Max Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective table size | mm | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Down speed | mm/s | 100 | 150 | 150 | 180 | 180 | 180 | 190 |

| Pressing speed | mm/s | 5~11 | 10~18 | 9~18 | 9~18 | 10~18 | 6~15 | 6~14 |

| Return speed | mm/s | 100 | 180 | 200 | 180 | 220 | 200 | 220 |

| Ejection cylinder force | KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Stroke of ejection cylinder | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 |