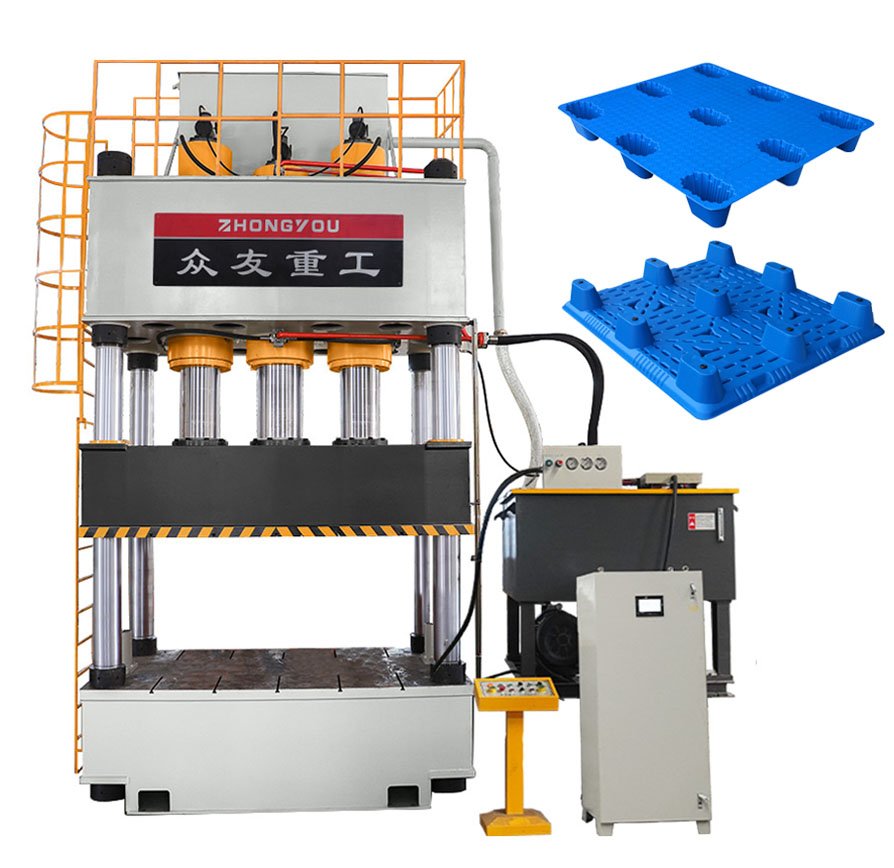

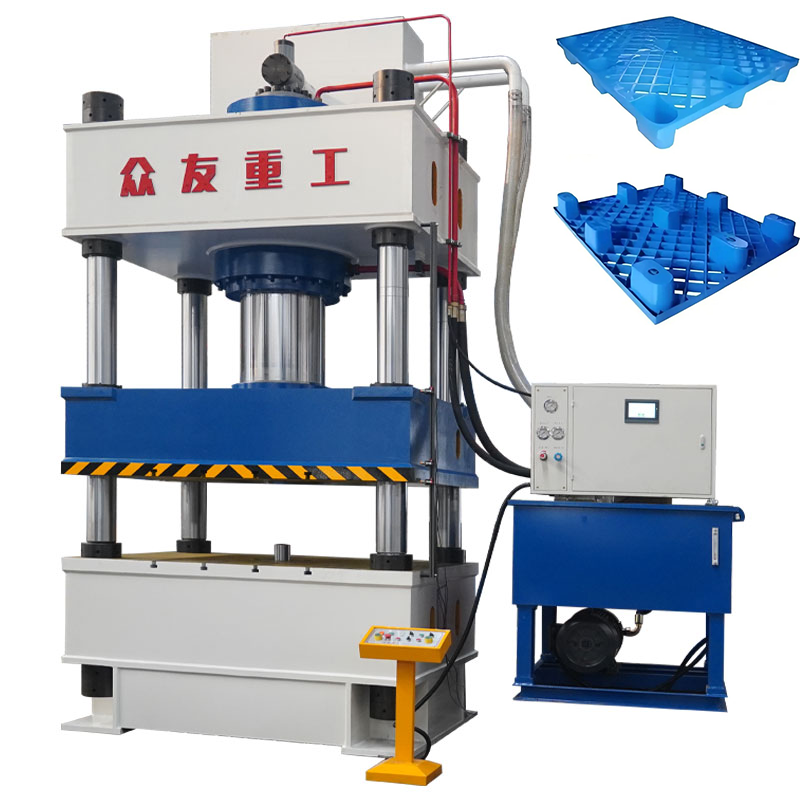

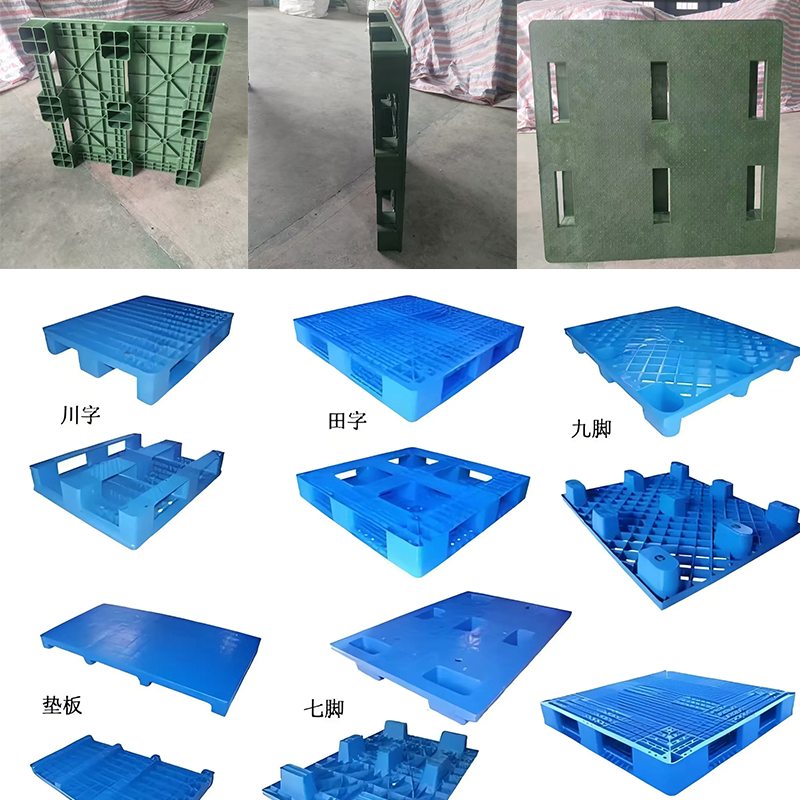

Hydraulic Press for Eco-Friendly Plastic Pallets Fiber Pallet Press

The plastic pallet hydraulic press is a highly integrated specialized production system centered around a large-frame hydraulic press, incorporating automation, temperature control, and precision molds. It is not merely a simple “press,” but the core of a complete, efficient, high-quality pallet production line.

Description

The plastic pallet hydraulic press is a highly integrated specialized production system centered around a large-frame hydraulic press, incorporating automation, temperature control, and precision molds. It is not merely a simple “press,” but the core of a complete, efficient, high-quality pallet production line.

1. Material Preparation → 2. Heating → 3. Feeding → 4. Clamping & Pressing → 5. Cooling & Curing → 6. Mold Opening & Ejection → 7. Finished Product

Material Preparation & Heating: Pre-cut GMT or LFT sheet material is uniformly heated in an infrared furnace until melted.

Feeding & Clamping: The softened sheet is rapidly transferred into the preheated lower mold. The hydraulic press drives the upper mold to descend and close rapidly.

Pressure Molding: Massive clamping force forces molten plastic to rapidly flow and fill the mold cavity. Fibers reorient under pressure, forming a high-strength skeleton.

Cooling and Setting: Cooling channels within the mold facilitate rapid cooling, setting the product.

Mold Opening and Ejection: The mold opens, and the ejection mechanism pushes out the formed tray.

Views: 0

Compression molding process

Customer Case

Technical Specifications

Detailed Parameters