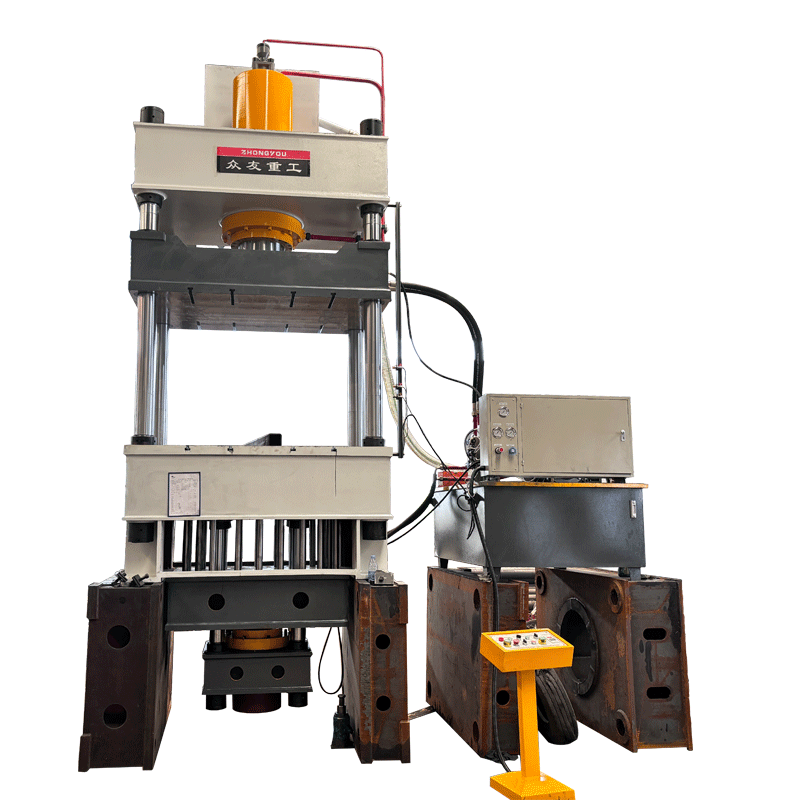

Grey Bucket Truck Stretching Machine with Hydraulic Pad Metal Stretch Forming Hydraulic Presses

Grey Bucket Truck Hydraulic Press is a special equipment designed for the moulding of metal compartments or frames of grey bucket trucks (trolleys, dump trucks, etc.) in the fields of construction, logistics, etc. Its core function is to achieve the processes of stretching, pressing, bending, calibrating and so on of the metal plates through the hydraulic system, which is equipped with the features of high precision, high efficiency and high adaptability.

Description

Grey Bucket Truck Hydraulic Press is a special equipment designed for the moulding of metal compartments or frames of grey bucket trucks (trolleys, dump trucks, etc.) in the fields of construction, logistics, etc. Its core function is to achieve the processes of stretching, pressing, bending, calibrating and so on of the metal plates through the hydraulic system, which is equipped with the features of high precision, high efficiency and high adaptability.

Strong versatility: it is suitable for the pressing process of malleable materials, such as powder product moulding, plastic product moulding, cold (hot) extruding metal moulding, thin plate stretching, as well as stamping, bending, flanging, calibrating and other processes.

Flexible operation: it adopts centralised control by push-buttons, which can realise three working modes: adjustment, manual and semi-automatic.The working pressure, pressing speed and slide stroke can be adjusted according to the needs of the process, and it can complete three kinds of processes: ejecting process, non-ejecting process and stretching process, and each kind of process provides two kinds of process actions for choice: fixed-pressure moulding process has the functions of pressure preservation, time-delay and automatic return after pressing.

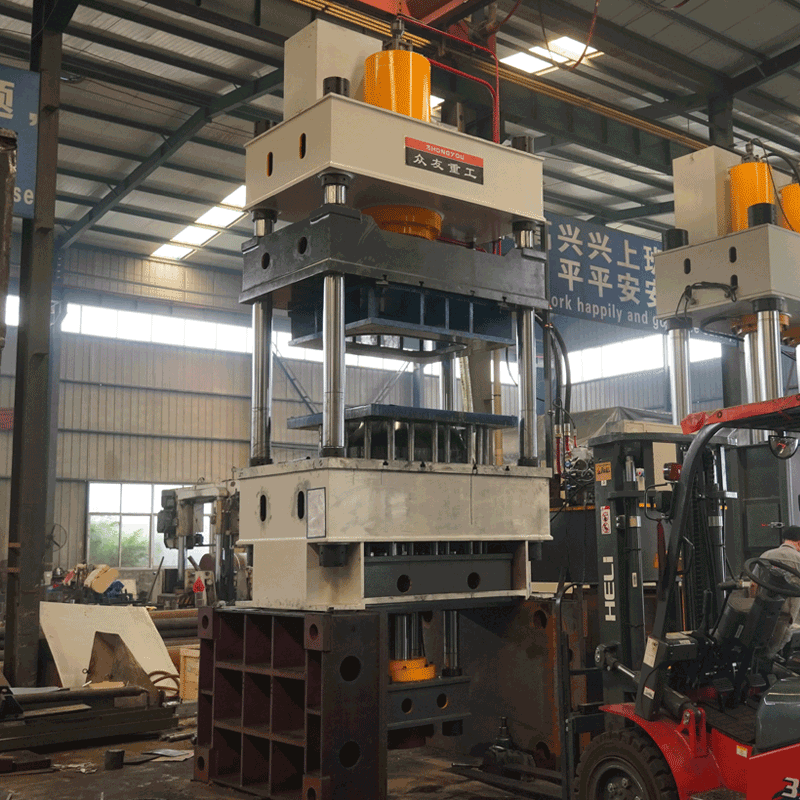

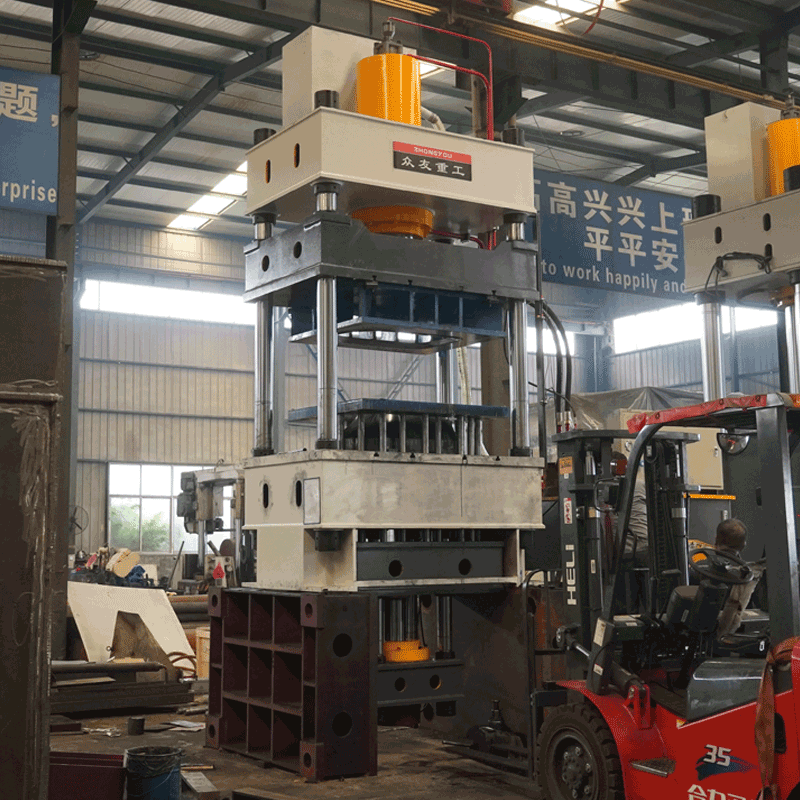

Reliable structure: The machine body is of three-beam and four-pillar structure, with all steel plates CO₂ welded and tempered and vibrated after welding to ensure that the machine body is not deformed.Hydraulic system is located in the machine body, beautiful appearance, easy to operate.

Excellent performance: the hydraulic system adopts battery reversing valve or cartridge valve, compact, reliable, sensitive action, fast speed, low energy consumption and low noise.The electrical system adopts PLC automatic control, with pointing and semi-automatic functions, and the stroke, pressure and speed of each running part can be self-adjustable within a certain range.

Views: 0

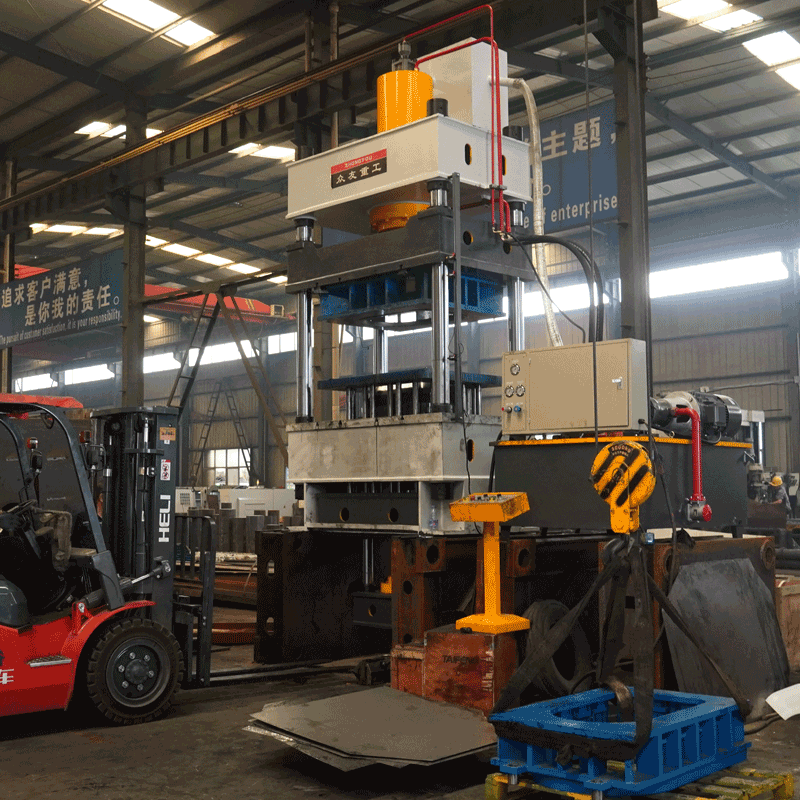

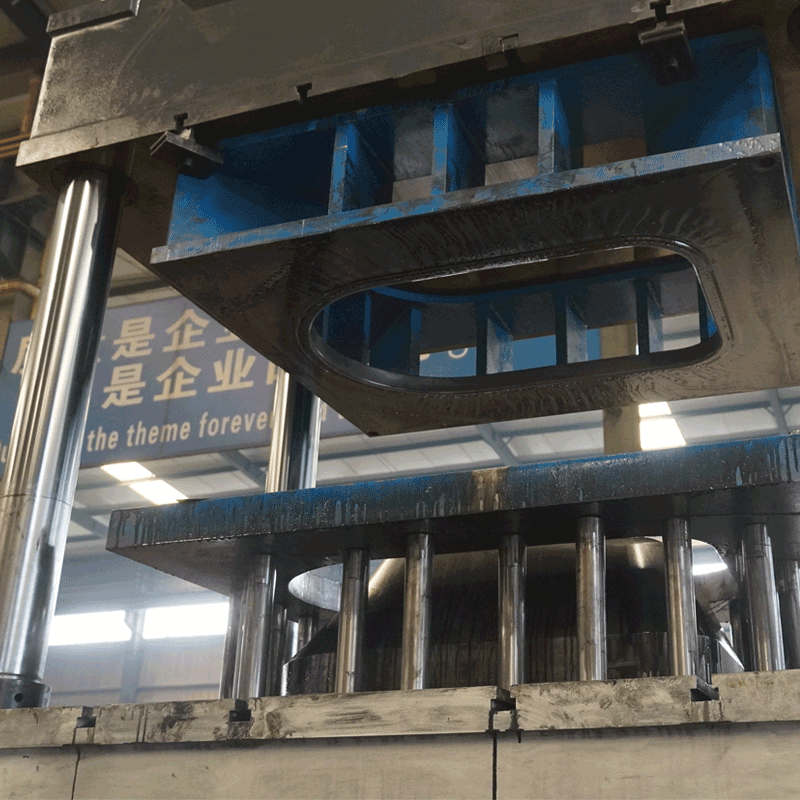

Compression molding process

Customer Case

Technical Specifications

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Detailed Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |