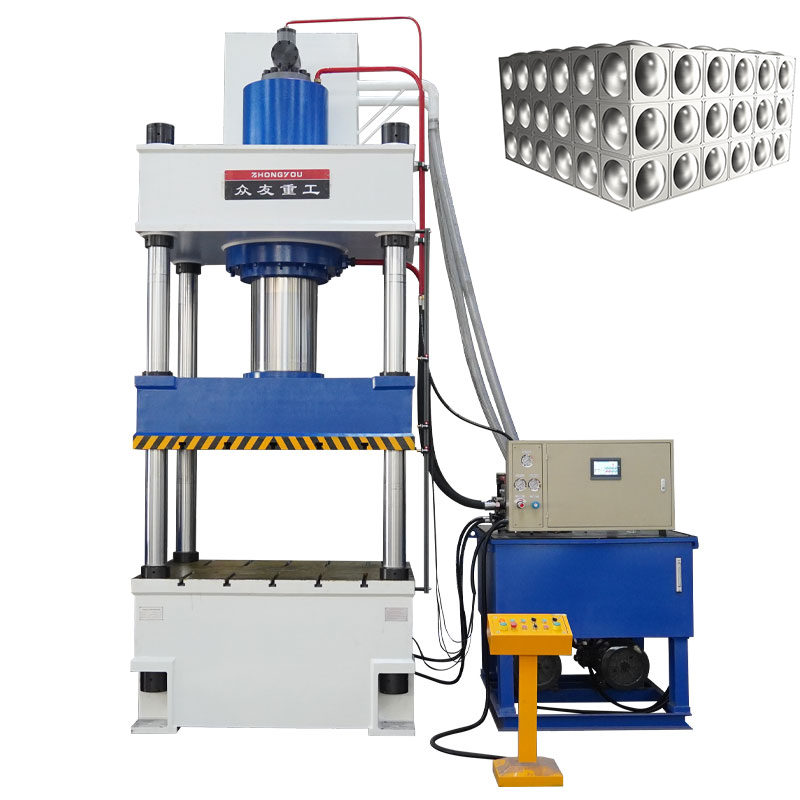

400ton Hydraulic Press Machine for Water Tank

This is a hydraulic press for manufacturing stainless steel water tanks, which can output a strong pressure of 400 tons (customizable) to press the water tank panels quickly and accurately. By changing different molds, the machine can press different sizes of water tank panels, including rectangular metal water tanks, fire fighting water tanks, large stainless steel water storage tanks and so on. At the same time, we can provide you with the whole stainless steel water tank production line equipment.

Description

This is a hydraulic press for manufacturing stainless steel water tanks, which can output a strong pressure of 400 tons (customizable) to press the water tank panels quickly and accurately. By changing different molds, the machine can press different sizes of water tank panels, including rectangular metal water tanks, fire fighting water tanks, large stainless steel water storage tanks and so on. At the same time, we can provide you with the whole stainless steel water tank production line equipment.

Use: Stamping the stainless steel plate into the side, top, bottom and other parts of the water tank through the mould.

Applicable scenes: stamping hydraulic press: used for mass production of standard size water tanks (such asDomestic roof water tank, fire water tank).

Hydraulic Expansion Machine: for manufacturing cylindrical water tanks (e.g. industrial water storage tanks), where the plates are shaped to fit the mould by internal pressure.

2. Welding and shaping

Purpose: correction and shaping after welding, eliminating welding deformation and ensuring the flatness of water tanks.

Applicable scenes: welding and shaping hydraulic press: for large water tanks (such as industrial circulatingwater tanks) for post-welding levelling.

Bending hydraulic press: bending the edge of the plate to form the reinforcement or connection structure of the water tank.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Detailed Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |