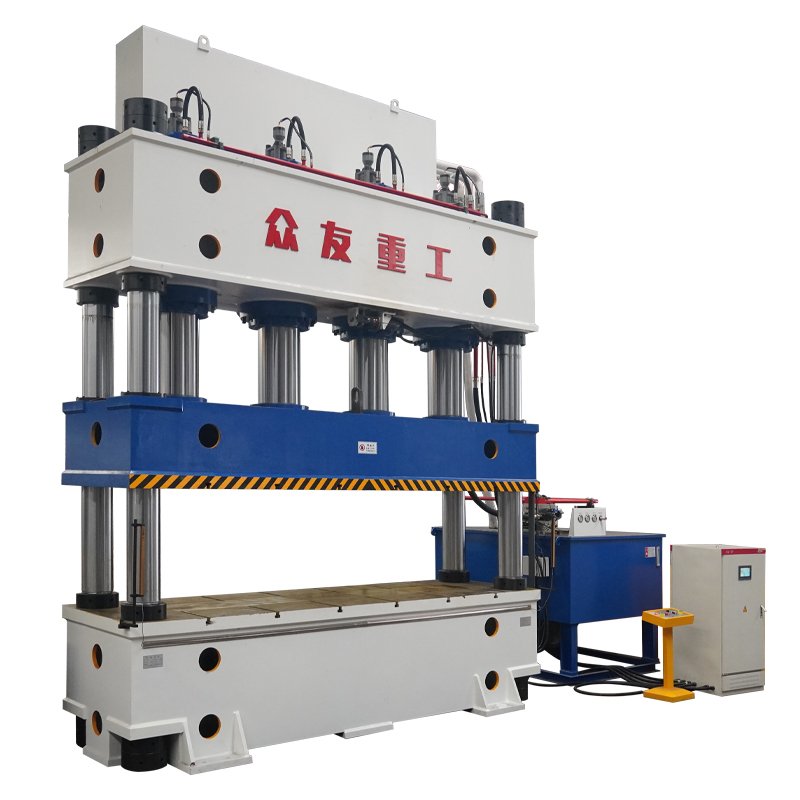

BMC/SMC Molding Compound Manhole Cover Hydraulic Press

Shandong Zhongyou Heavy Industry custom-built a 315-ton three-beam four-column hydraulic press for a Bangladeshi client. This hot-pressing equipment is suitable for manufacturing resin manhole covers and storm drain grates.

Description

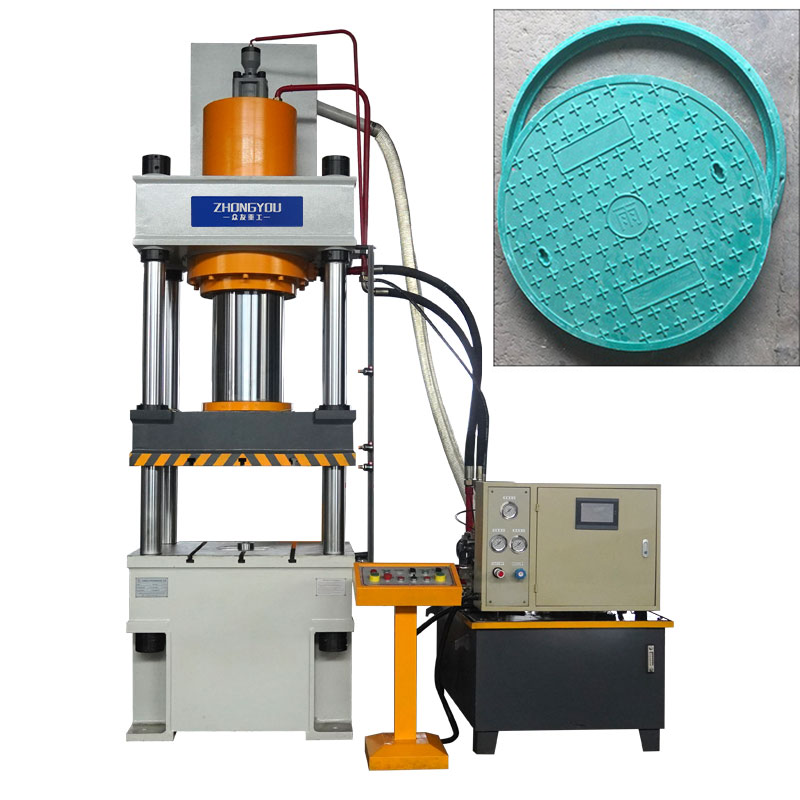

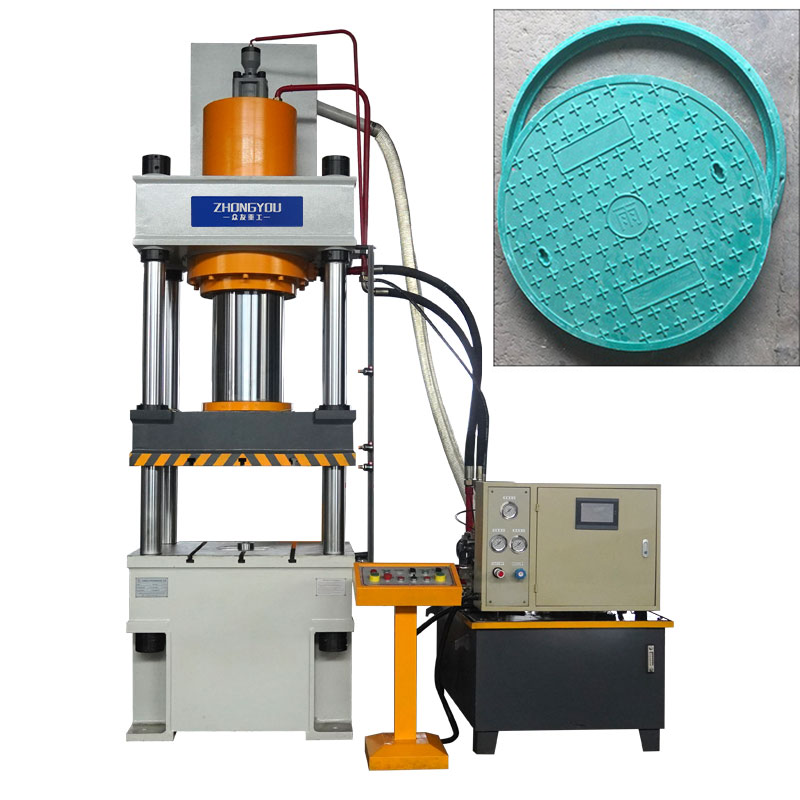

Resin Manhole Cover Forming Hydraulic Press

Utilizing a hydraulic drive system, this press molds composite materials (such as BMC/SMC molding compounds) into manhole covers through high-temperature, high-pressure compression.

Resin Manhole Cover Forming Hydraulic Press

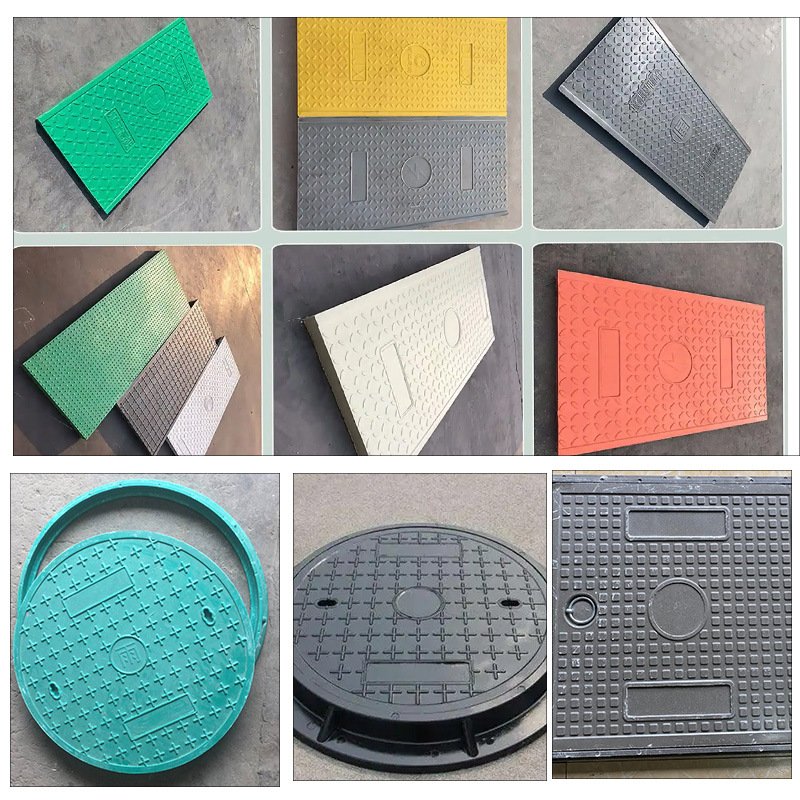

Widely applied in the following fields:

Municipal Engineering:

Manufacturing resin manhole covers for urban roads, plazas, and other public spaces.

Pipeline Maintenance:

Producing sewer covers, storm drain grates, and other pipeline accessories.

Composite Processing: Pressing SMC/BMC products like power slope protection plates, cable trench covers, and tree pit protection plates.

Key Advantages

High Production Efficiency: Automated cycles with short cycle times (typically several minutes per mold).

Superior Product Quality: Precise dimensions, high surface finish, dense internal structure, and consistent strength.

Design Flexibility: Capable of molding complex structures and manhole covers featuring three-dimensional patterns or logos.

High Material Utilization: Minimal waste (flash can be recycled).

Views: 0

Compression molding process

Customer Case

Technical Specifications

Detailed Parameters