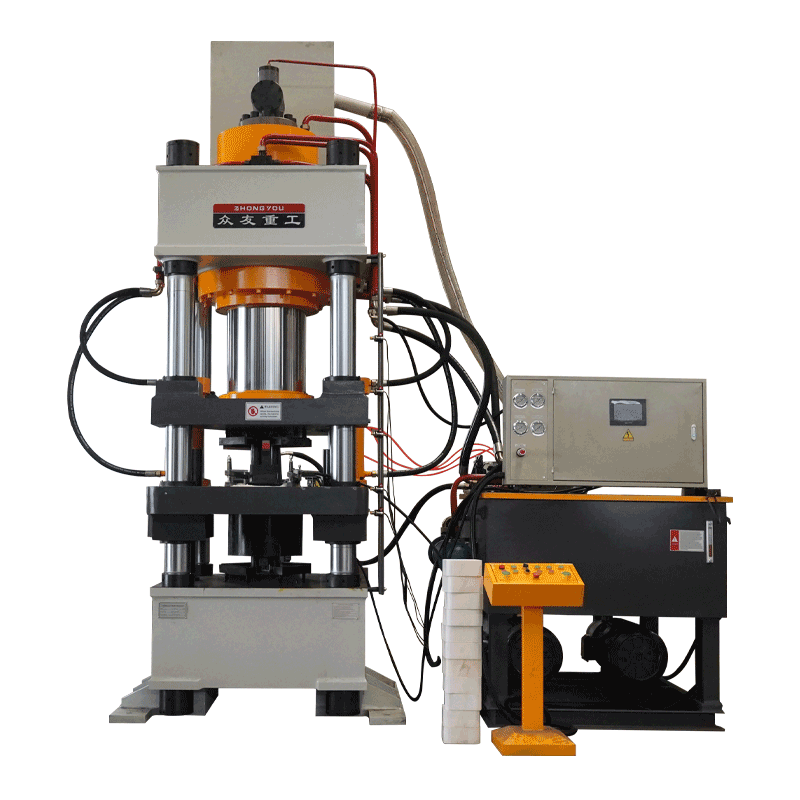

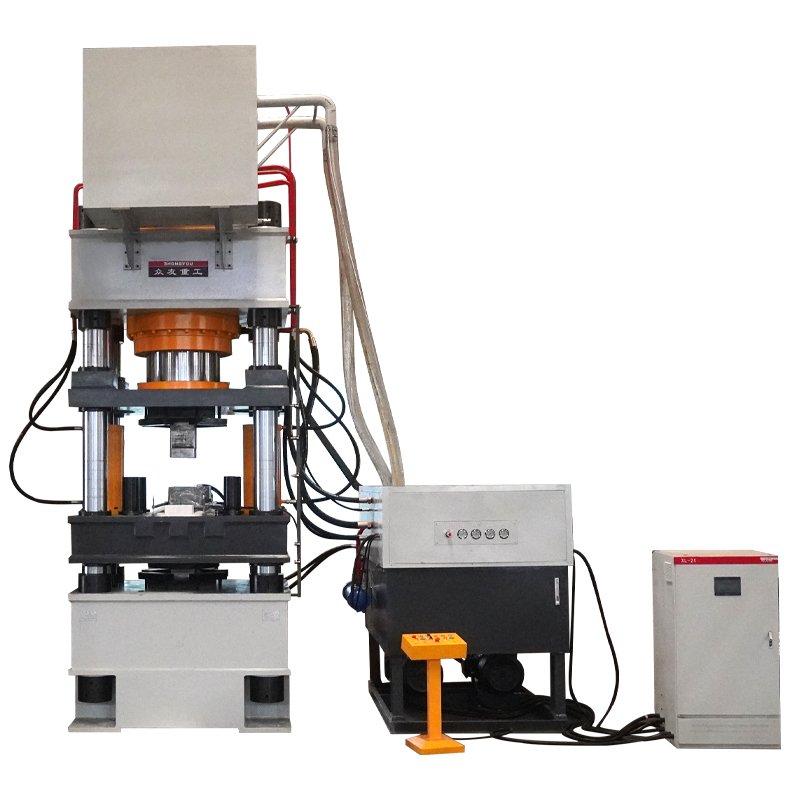

800 tons of cattle and sheep licking brick production line

800 tons of cattle and sheep lick brick hydraulic press is designed for cattle and sheep and other livestock feed additives (lick brick) production of large-scale molding equipment, mainly used for minerals, vitamins, trace elements and other mixed raw materials compression molding, made of high-density nutrient blocks that are easy for livestock to lick!

Description

The core objective of the cattle and sheep lick brick hydraulic press is to press loose powdered feed materials (such as calcium and phosphorus salts, trace elements, molasses binders, etc.) into lick brick products with uniform density, moderate hardness and regular shape through high-pressure molding process. Its key roles include:

Ensure balanced nutrition: precise pressure control ensures uniform mixing of raw materials and avoids segregation of nutrients;

Enhance palatability: reasonable hardness and porosity (usually density 1.8-2.2g/cm³) can extend licking time and promote active intake of livestock;

Improve production efficiency: replace traditional manual or small tonnage equipment to realize large-scale production (daily output of a single shift can be up to thousands of pieces)

800 tons of cattle and sheep lick brick hydraulic press is the core equipment for large-scale production of high-quality lick brick, and its performance directly affects the nutritional uniformity, hardness and production efficiency of the product. Users need to combine their own production capacity, product specifications and budget, focusing on the pressure accuracy of the equipment, mold adaptability and automation level, in order to ensure that the production of high-quality lick bricks in line with the needs of breeding.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

Detailed Parameters

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |