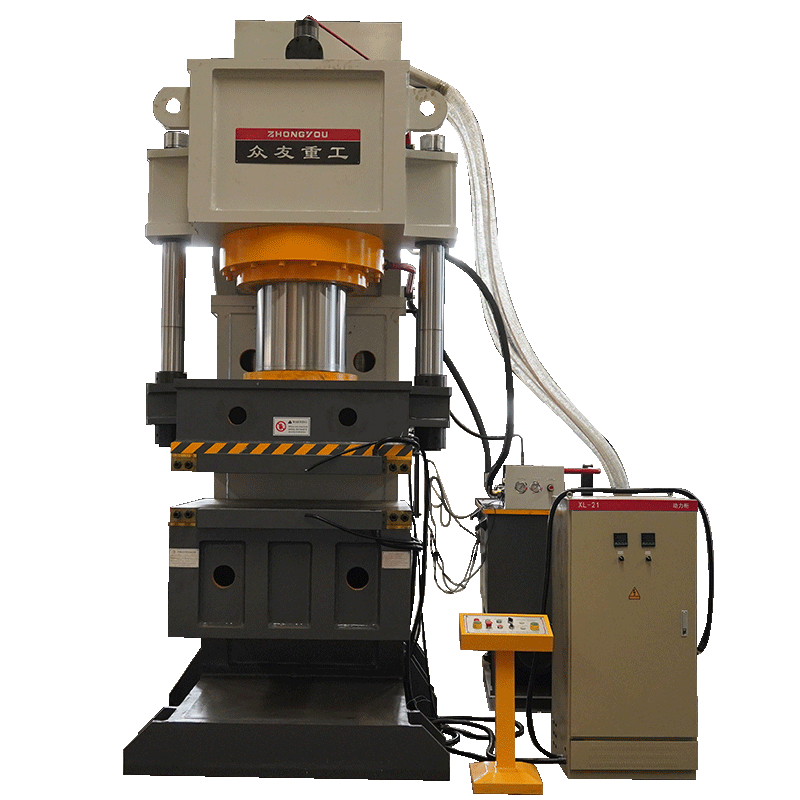

700T single arm hydraulic press with electric heating and water-cooled tubes

700 tonne single arm hydraulic press with water electric heating and water-cooled tubes is the core equipment in the field of composite materials and rubber products, etc. Its single arm structure, large tonnage pressure and precise temperature-controlled cooling function can meet the demand of high precision and high efficiency production.When selecting the model, you need to combine the process requirements, material characteristics and budget, choose manufacturers with customised capabilities, and pay attention to the maintenance and safe operation of the equipment.

Description

700 tonne single arm hydraulic press with water electric heating and water-cooled tubes is the core equipment in the field of composite materials and rubber products, etc. Its single arm structure, large tonnage pressure and precise temperature-controlled cooling function can meet the demand of high precision and high efficiency production.When selecting the model, you need to combine the process requirements, material characteristics and budget, choose manufacturers with customised capabilities, and pay attention to the maintenance and safe operation of the equipment.

Single arm structure

Adopting C-type single-arm design, the pressure of the main cylinder reaches 700 tonnes, which is suitable for the scenario that requires large tonnage and flexible operation space.Split pump station design can reduce the impact of equipment vibration on precision. The upper and lower tables are equipped with heating plates to support high temperature hot press moulding.

Water and electric heating system

The heating plate is built-in electric heating tube or water circulation heating channel, which can achieve precise temperature control (e.g. ±2℃).The servo system adjusts the temperature in real time to ensure that the material is heated uniformly during the hot pressing process, avoiding local overheating or undercuring.

Water-cooled tube cooling system

The hydraulic press is equipped with an independent water-cooling circuit, which cools down the hydraulic cylinder, oil circuit or mould through cooling tubes.The cooling system can be linked with the heating system to achieve rapid cooling and shaping after hot pressing and moulding to improve production efficiency.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

Detailed Parameters

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |