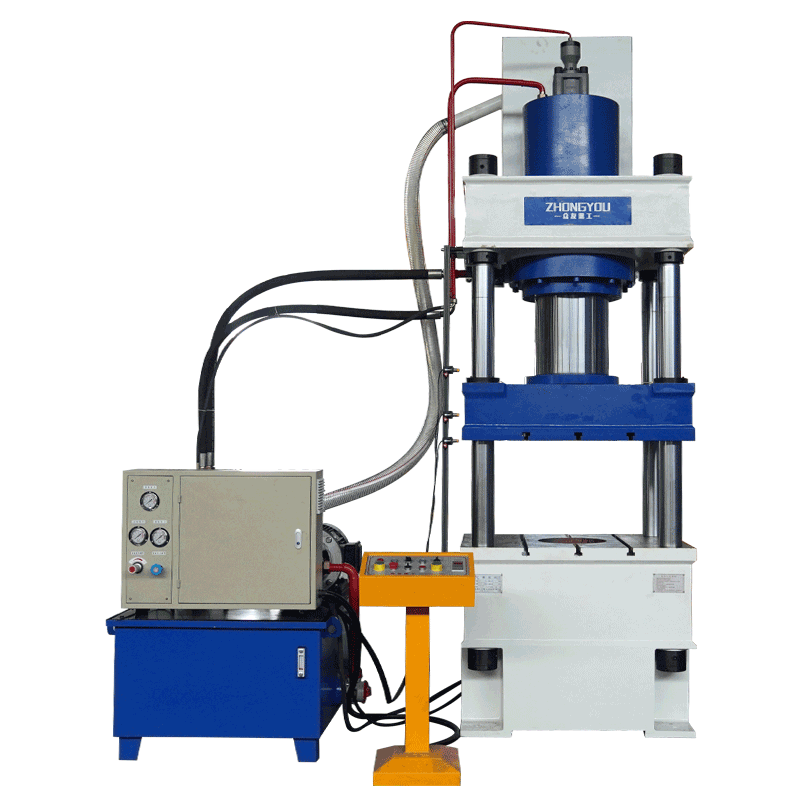

315 tons four column sand brick molding hydraulic machine

315 tons of sand brick molding hydraulic press” is a hydraulic power source, designed for pressing sand bricks (including industrial waste bricks, environmental bricks, etc.) designed for special molding equipment, suitable for sand, cement, fly ash, slag and other raw materials mixed through the high-pressure molding process to make all kinds of architectural bricks.

Description

315 tons of sand brick molding hydraulic press” is a hydraulic power source, designed for pressing sand bricks (including industrial waste bricks, environmental bricks, etc.) designed for special molding equipment, suitable for sand, cement, fly ash, slag and other raw materials mixed through the high-pressure molding process to make all kinds of architectural bricks.

Building materials: efficient production of sand bricks, no-burn bricks, hollow bricks, pavement bricks, supporting the integration of roughing and finishing, improving production efficiency and precision (micron level) to meet the needs of green building.

Metal Processing: Used in the molding of automotive coverings, boiler headers, stainless steel hand wash tanks, ship parts, aerospace parts, and is suitable for precision machining of high-strength alloys (e.g., titanium alloys, aerospace aluminum).

Composite materials: support for thermoplastic materials such as carbon fiber, glass fiber reinforced plastic, polyethylene and other thermoplastic materials hot press molding, used in new energy, rail transportation and other fields.

Environmental protection and energy saving: some models adopt energy-saving motors, optimized design of cooling system, combined with 5G to realize remote operation and maintenance and data interconnection, reducing energy consumption and maintenance costs.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

Detailed Parameters

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |