315-Ton Plastic Flower Pot Molding Hydraulic Press Composite Material Hot Press

Plastic flower pot forming hydraulic presses are specialized hot-press/molding equipment. They deliver high pressure through a frame-type or four-column body, equipped with precision heating and temperature control systems to provide high temperatures. Using custom patterned molds, they mold reinforced composite plastic materials into sturdy and aesthetically pleasing plastic flower pots in a single press operation. For producing mid-to-high-end, irregularly shaped, and large-scale decorative flower pots, this is a more suitable and efficient choice than traditional injection molding processes.

Description

Plastic flower pot forming hydraulic presses are specialized hot-press/molding equipment. They deliver high pressure through a frame-type or four-column body, equipped with precision heating and temperature control systems to provide high temperatures. Using custom patterned molds, they mold reinforced composite plastic materials into sturdy and aesthetically pleasing plastic flower pots in a single press operation. For producing mid-to-high-end, irregularly shaped, and large-scale decorative flower pots, this is a more suitable and efficient choice than traditional injection molding processes.

Urban Greening: Produces large plastic planters for street and park landscaping.

Flower Markets: Mass-produces small-to-medium planters to meet household and commercial floral cultivation needs.

Industrial Manufacturing: Extends equipment utility by molding deep-cavity products like plastic septic tanks, trays, and pallets.

Views: 0

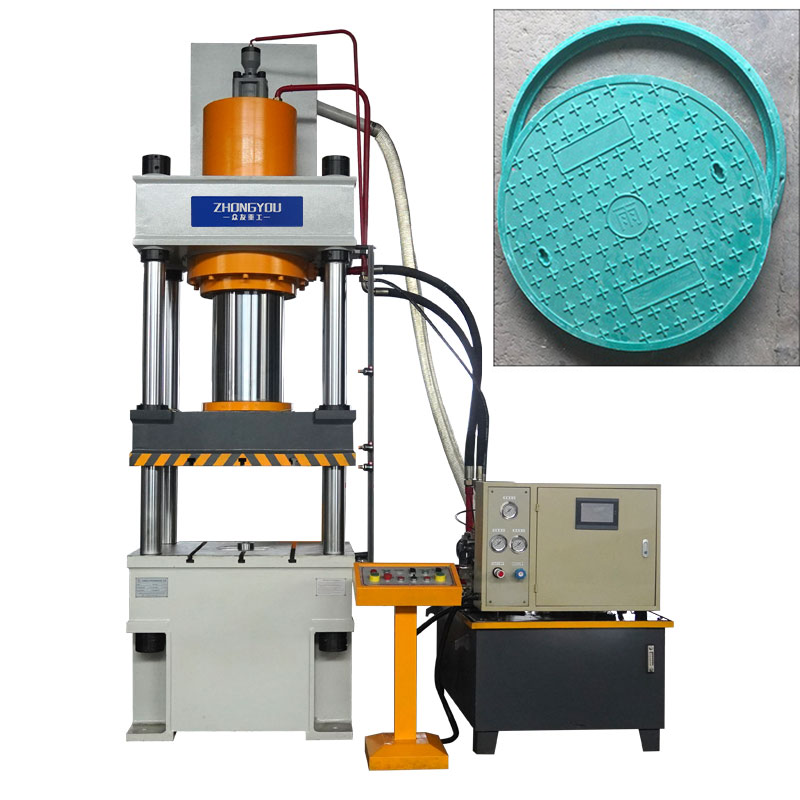

Compression molding process

Customer Case

Technical Specifications

Detailed Parameters