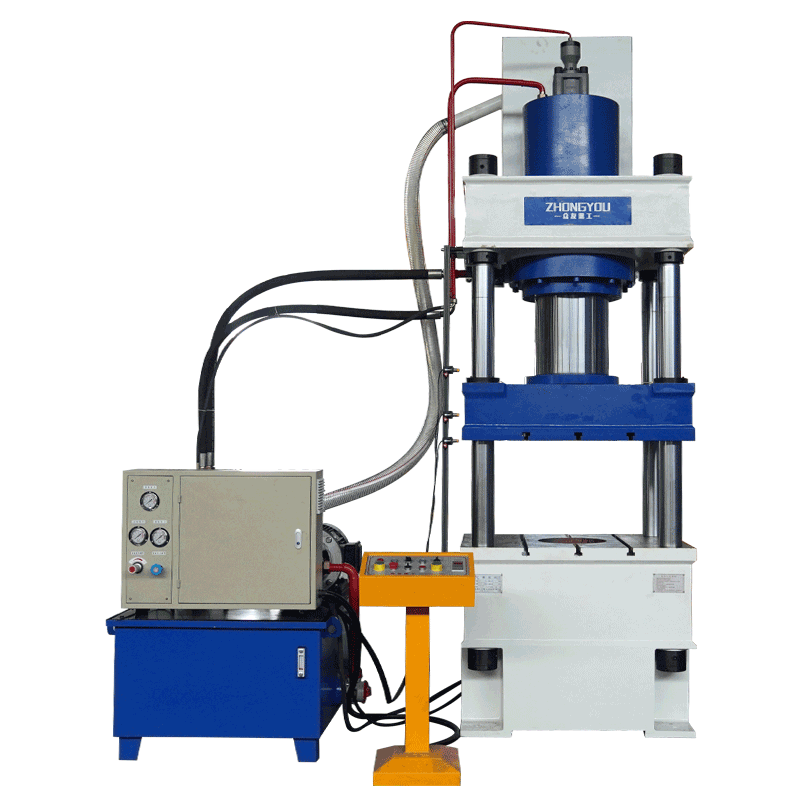

315-ton PE Sand Paver Forming Hydraulic Press

PE sand and gravel moulding hydraulic press can efficiently produce PE sand and gravel with consistent quality and shape, which is widely used in construction and decoration industry.

Description

PE sand and gravel moulding hydraulic press can efficiently produce PE sand and gravel with consistent quality and shape, which is widely used in construction and decoration industry.

Working principle of PE sand pavement tile production:

1. Preparation: pre-treated PE sand and additives (e.g. pigments, reinforcing agents) are thoroughly mixed and put into moulds. 2.

. Hydraulic moulding: the mould filled with PE sand is put into the hydraulic press.The hydraulic pump is activated and pressure is delivered through the hydraulic system.The hydraulic cylinder transfers this pressure to the mould, compressing the PE sand. 3 .

. Forming process: The pressure ensures that the PE sand completely fills the mould cavity and is tightly bonded.The pressure and the moulding time can be adjusted to achieve the desired density and strength of the pavement blocks.4 .

. Curing and demoulding: After holding the pressure for a certain period of time, the hydraulic press stops.The pavement bricks are cured inside the mould for a certain period of time.After curing, the mould is opened and the formed pavement bricks are taken out.

Key components of PE sand pavement brick moulding hydraulic press:

1. Hydraulic system: It consists of hydraulic pump, hydraulic cylinder and pipeline.The hydraulic pump delivers pressurised hydraulic oil to the hydraulic cylinder, and the control valve regulates the pressure. 2.

. Moulds: metal parts with precise dimensions and patterns to define the shape and surface texture of the pavement bricks.3 .

. Pressure regulator: allows the operator to fine-tune the compression force applied to the PE sand to ensure optimal pavement tile density and structural integrity.4 .

. Control system: monitors and automates the moulding process.It adjusts parameters such as pressure, cycle time and temperature to ensure consistent product quality.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Name | Unit | YQ32-400 | YQ32-500 | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective Area of Workbench | mm | 1250×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 150 | 100 | 180 | 180 | 190 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 7-18 | 10-18 | 6-15 | 6-14 |

| Return Speed | mm/s | 100 | 180 | 200 | 90 | 220 | 200 | 220 |

| Ejecting Force | kN | 630 | 1000 | 1000 | 400 | 1000 | 1000 | 1600 |

| Maximum Ejecting Stroke | mm | 300 | 300 | 300 | 200 | 300 | 300 | 300 |

Detailed Parameters

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Name | Unit | YQ32-400 | YQ32-500 | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective Area of Workbench | mm | 1250×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 150 | 100 | 180 | 180 | 190 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 7-18 | 10-18 | 6-15 | 6-14 |

| Return Speed | mm/s | 100 | 180 | 200 | 90 | 220 | 200 | 220 |

| Ejecting Force | kN | 630 | 1000 | 1000 | 400 | 1000 | 1000 | 1600 |

| Maximum Ejecting Stroke | mm | 300 | 300 | 300 | 200 | 300 | 300 | 300 |