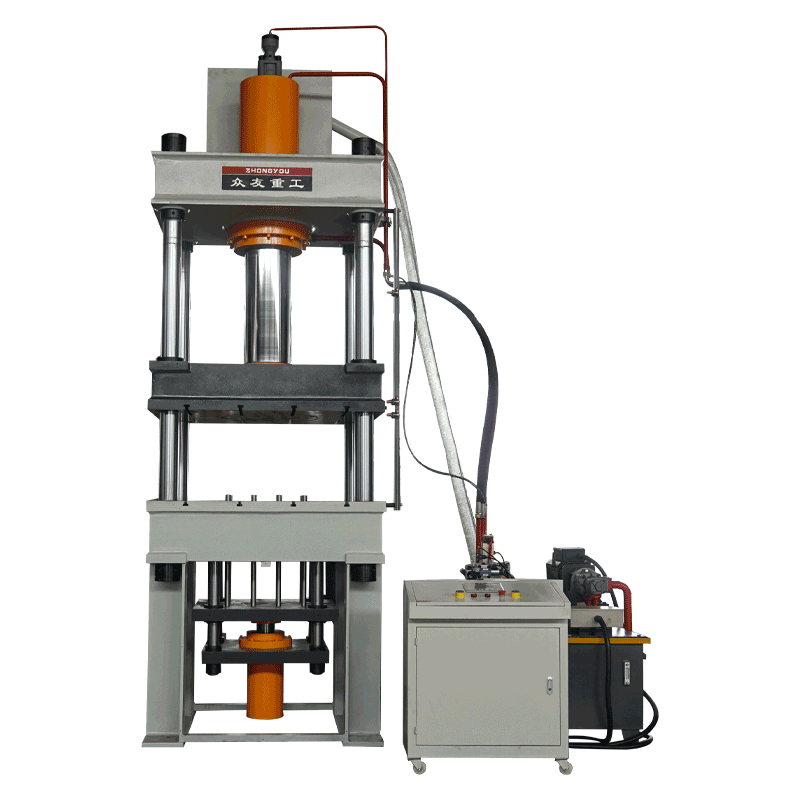

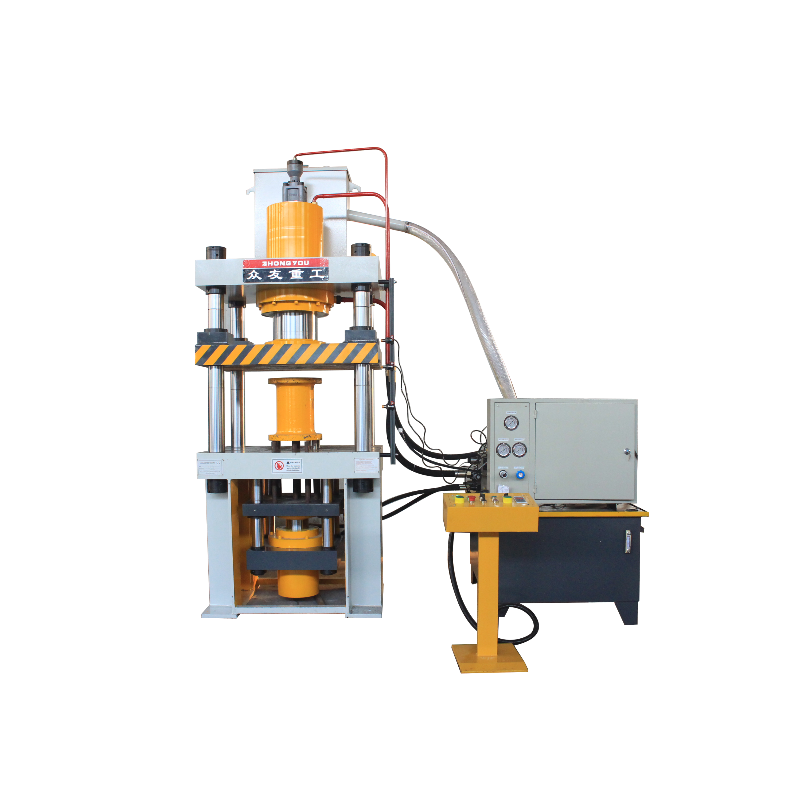

315 Ton Hydraulic Press Machine for Wheel Barrow

Grey Bucket Truck Hydraulic Press is a kind of special equipment designed for metal plate forming, stretching, stamping and other processes of Grey Bucket Truck (transport truck bucket for construction site), which is widely used in construction, logistics, hardware processing and other industries.

Description

Grey Bucket Truck Hydraulic Press is a kind of special equipment designed for metal plate forming, stretching, stamping and other processes of Grey Bucket Truck (transport truck bucket for construction site), which is widely used in construction, logistics, hardware processing and other industries.

Core Functions

1. Plate forming

Through the high-pressure hydraulic system to metal plate (such as iron plate, aluminium plate) for stretching, bending, stamping, to achieve the ash bucket truck bucket one-time forming, improve production efficiency and product quality.

2. Multi-process adaptation

Supporting various processes such as drop, correction, pressing, punching, etc., to meet the processing needs of different parts of the grey bucket truck.

3. Automation control

Adopt PLC (Programmable Logic Controller) or button centralised control, support pointing, semi-automatic and full-automatic modes, flexible and safe operation.

Second, the technical characteristics

1. Solid structure

Adopting three-beam and four-pillar or gantry structure, the machine body is welded by high-strength steel plate, tempered and vibrated to ensure long-term use without deformation.

2. Efficient hydraulic system

◦ Use cartridge valve integrated hydraulic system, sensitive action, good sealing, reduce the risk of leakage.

◦ Equipped with high pressure pump and oil filter to ensure the cleanliness of hydraulic oil and prolong the equipment life.

◦ Some models support water-cooled cooling to adapt to high-intensity continuous operation.

3. High Precision Guiding

The four-column guiding structure provides high guiding accuracy and resistance to lateral force, ensuring stable dimensions of moulded parts.

4. Safety Protection

◦ Equipped with photoelectric protection device, emergency stop button and overload protection system to prevent operation accidents.

◦ Hydraulic system is equipped with pressure gauge and limit device to monitor the working status in real time.

III. Applicable Scenarios

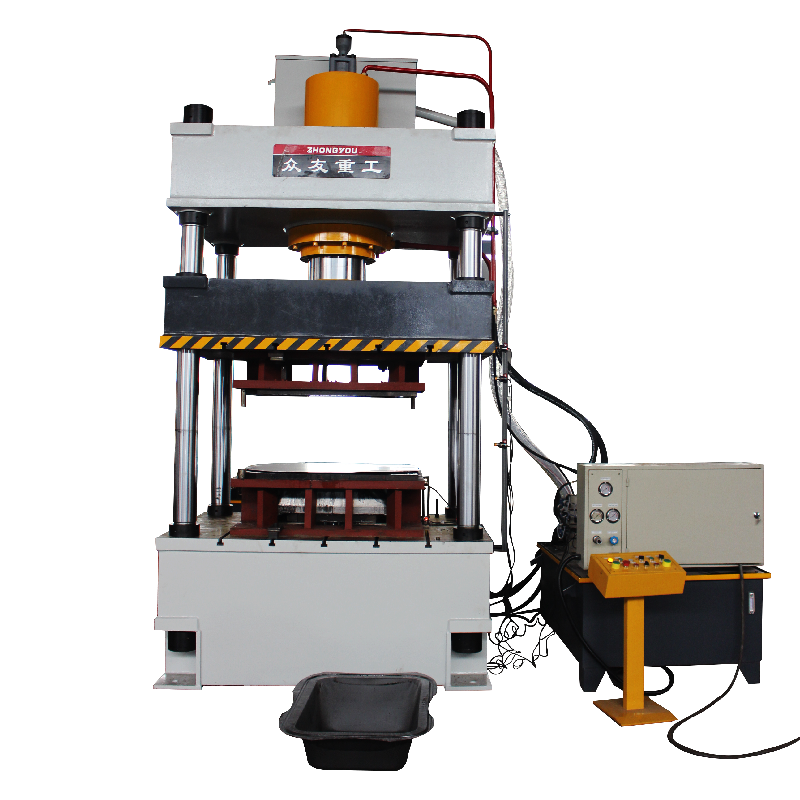

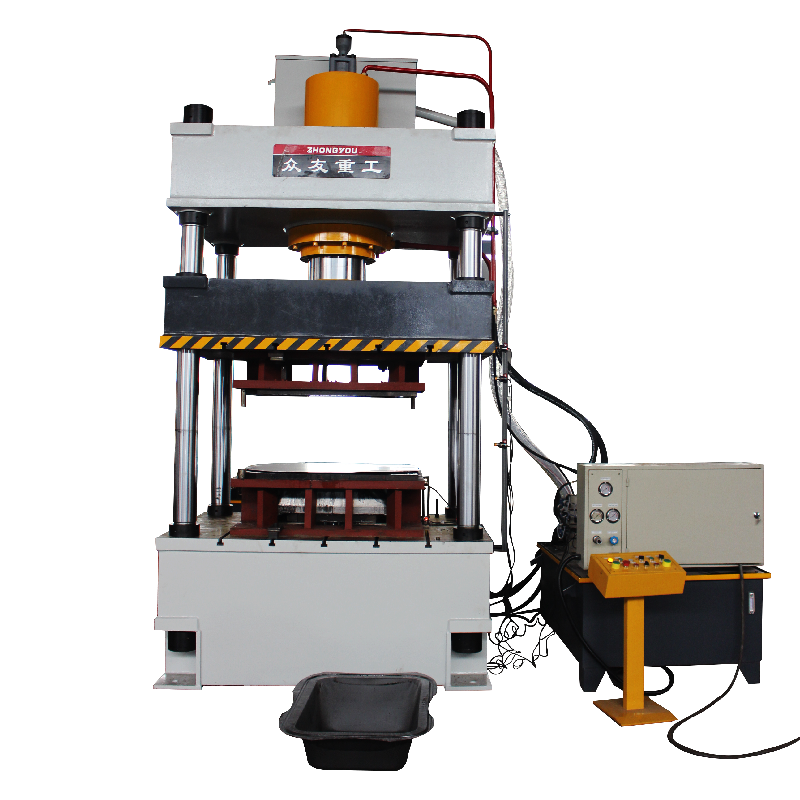

– Grey hopper truck production: stretch forming of metal parts such as buckets, tipping buckets and brackets.

– Hardware processing: metal sheet stamping, bending, flanging and other processes.

– Construction machinery: parts processing of other site transport equipment.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Detailed Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |