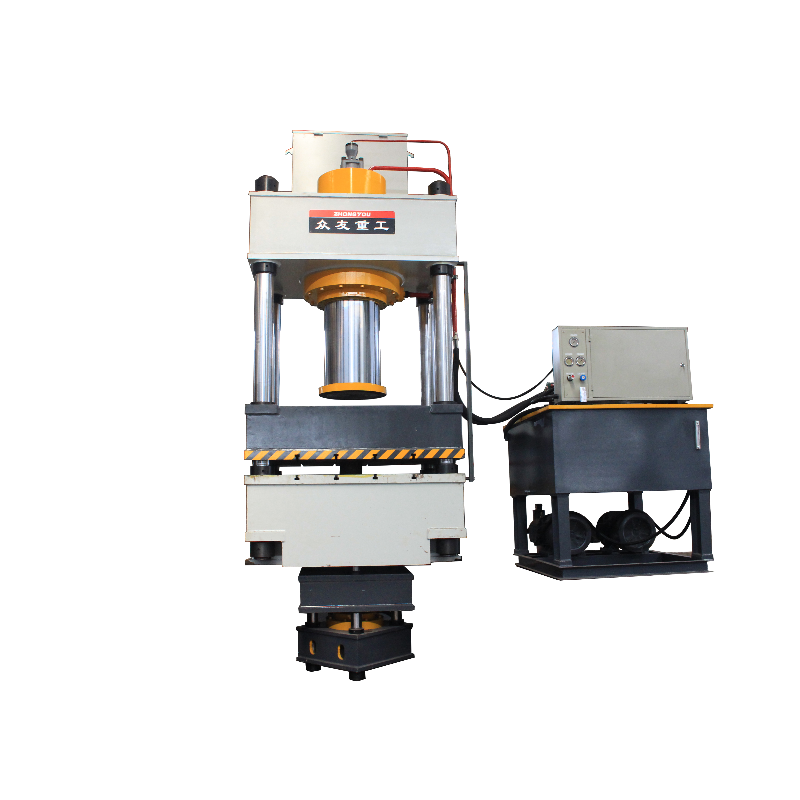

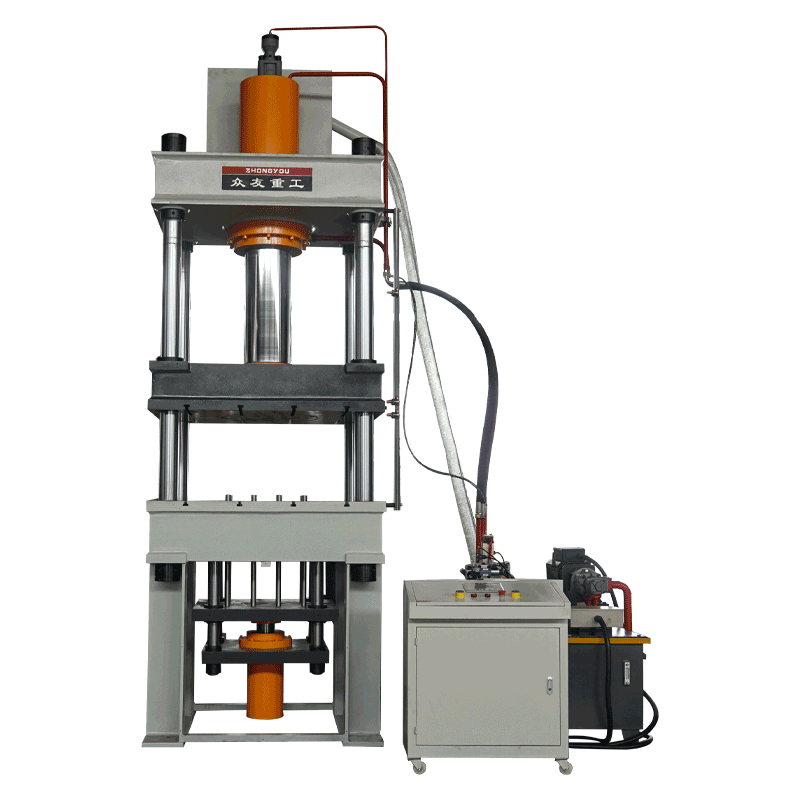

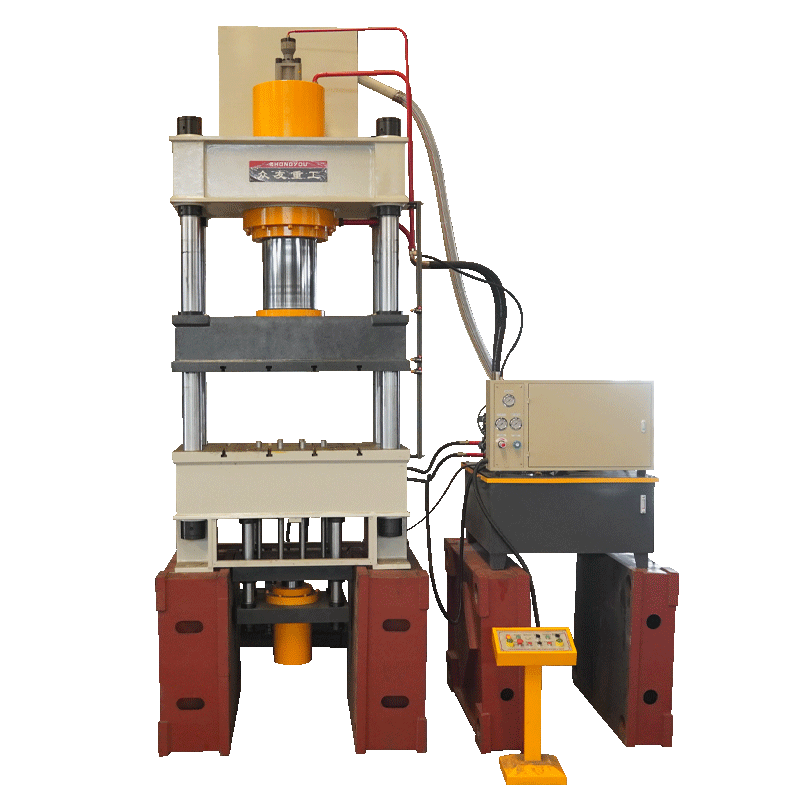

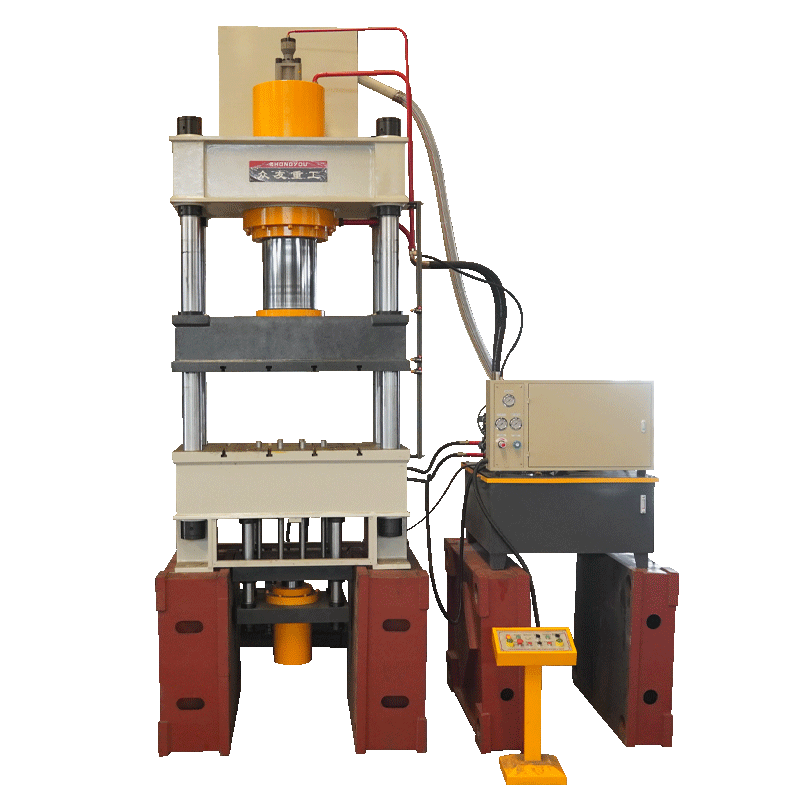

315 Ton Hydraulic Press Machine for Deep Drawing

315 tonne metal stretching machine hydraulic press is a kind of high-precision pressure processing equipment using hydraulic transmission technology, mainly used for metal plate stretching, forming, bending, calibration and other processes, commonly used in automotive manufacturing, aerospace, pressure vessels,Hardware products and other industries.

Description

315 tonne metal stretching machine hydraulic press is a kind of high-precision pressure processing equipment using hydraulic transmission technology, mainly used for metal plate stretching, forming, bending, calibration and other processes, commonly used in automotive manufacturing, aerospace, pressure vessels,Hardware products and other industries.

Core Function: Provide stable and controllable high pressure (315 tonnes ≈ 3150kN) output to adapt to the plastic deformation needs of metal materials.

– Typical applications: auto body parts stretching, aluminium alloy wheel forming, stainless steel kitchenware stamping, etc.

II. Working Principle

1. Power transmission

◦ Hydraulic pumps (usually piston pumps) convert electrical/mechanical energy into high-pressure oil (pressure up to 25~35MPa).

◦ The hydraulic fluid drives the main hydraulic cylinder through the control valve group, generating a huge pressure acting on the mould.

2. Stretching process

◦ The upper mould is fixed and the lower mould pushes the sheet through the hydraulic cylinder, gradually stretching and forming the sheet to avoid material tearing.

3. Pressure control

◦ Proportional servo valve or PLC closed-loop control is adopted to realise precise adjustment of pressure and displacement.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Detailed Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |