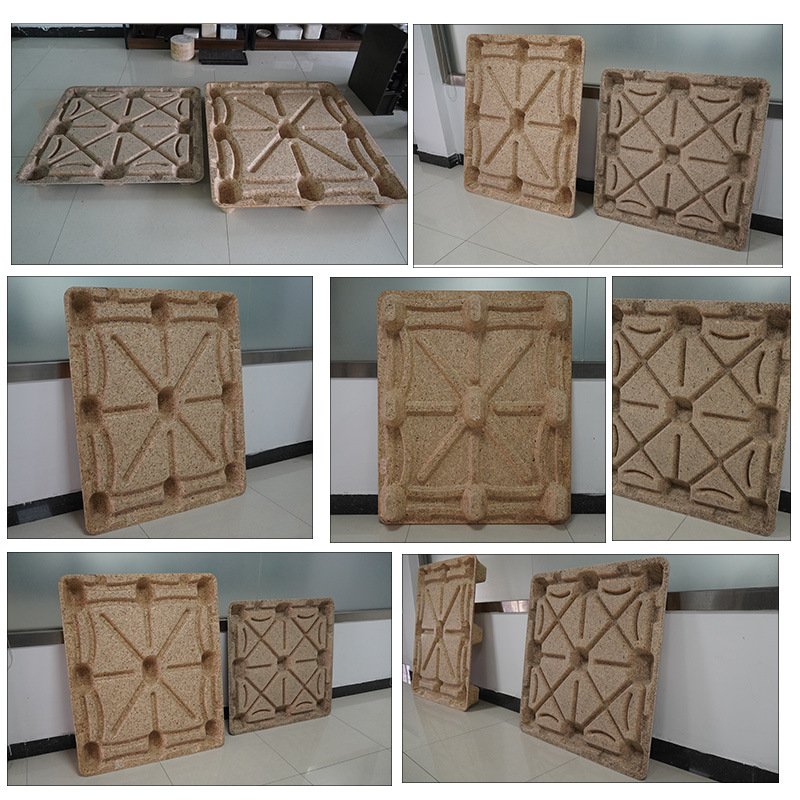

1250-Ton Wood Chip Pallet Hydraulic Press Sawdust Pallet Press

The 1250-ton wood chip pallet hydraulic press is a large-scale, professional biomass fuel forming machine. It is primarily used to compress biomass materials such as wood chips, sawdust, and straw into high-density pallets or block fuels under high pressure (serving as intermediate products for pellet fuel or directly forming fuel blocks).

Description

The 1250-ton wood chip pallet hydraulic press is a large-scale, professional biomass fuel forming equipment. It is primarily used to compress biomass materials such as wood chips, sawdust, and straw into high-density pallets or block fuels under high pressure (serving as intermediate products for pellet fuel or directly formed fuel blocks).

Wood Chip Pallet Production: Process Flow: Raw Material Pre-treatment (cutting, chipping, grinding, drying) → Adhesive Mixing → Molding → Edge Grinding. Applicable Materials: Nine-leg plastic pallets, bamboo-plastic composite pallets, etc.

Energy-Efficient & High-Performance: The servo-driven hydraulic system offers rapid response, high load capacity, and substantial power, achieving lower energy consumption compared to traditional hydraulic equipment.

Environmentally friendly materials: Utilizes wood chips, straw, waste chemical fibers, etc., as raw materials to reduce production costs and minimize environmental pollution.

Views: 0

Compression molding process

Customer Case

Technical Specifications

Detailed Parameters