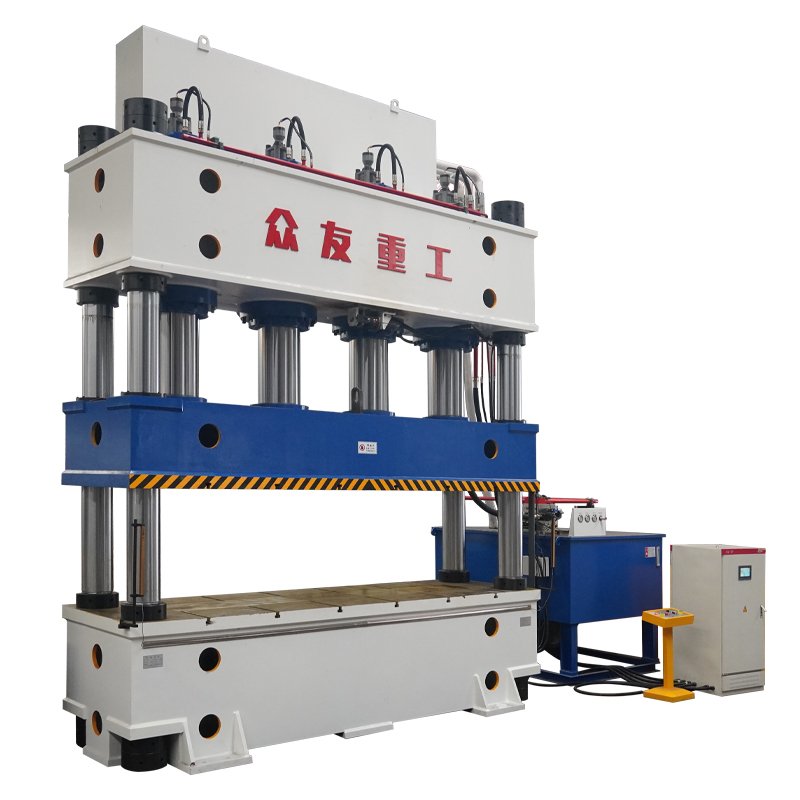

1000-Ton Glass-Fiber Reinforced Plastic Septic Tank Forming Hydraulic Press

This is a large-tonnage, large-platen hydraulic press designed for hot compression molding. Its core function is to cure glass fiber-reinforced materials and resin within metal molds under high temperature and pressure, producing seamless, monolithic fiberglass septic tanks in a single molding operation.

Description

This is a large-tonnage, large-platen hydraulic press designed for hot compression molding. Its core function is to cure glass fiber reinforced materials and resin within metal molds under high temperature and pressure, producing seamless, monolithic fiberglass septic tanks in a single molding operation.

High Pressure Output: Capable of handling large workpieces to meet the high-pressure demands of composite material compression molding.

Precision Control: Advanced control systems ensure accurate displacement and pressure regulation, guaranteeing consistent molding quality.

Versatile Process Compatibility: Suitable for composite molding, stamping/drawing, powder block compaction, and other processes.

High Efficiency: High automation levels boost production efficiency and reduce costs.

Beyond fiberglass septic tanks, this equipment can also mold other composite powder products, lump/bulk fiberglass molding compounds, sheet molding compounds, and similar materials.

Views: 0

Compression molding process

Customer Case

Technical Specifications

Detailed Parameters