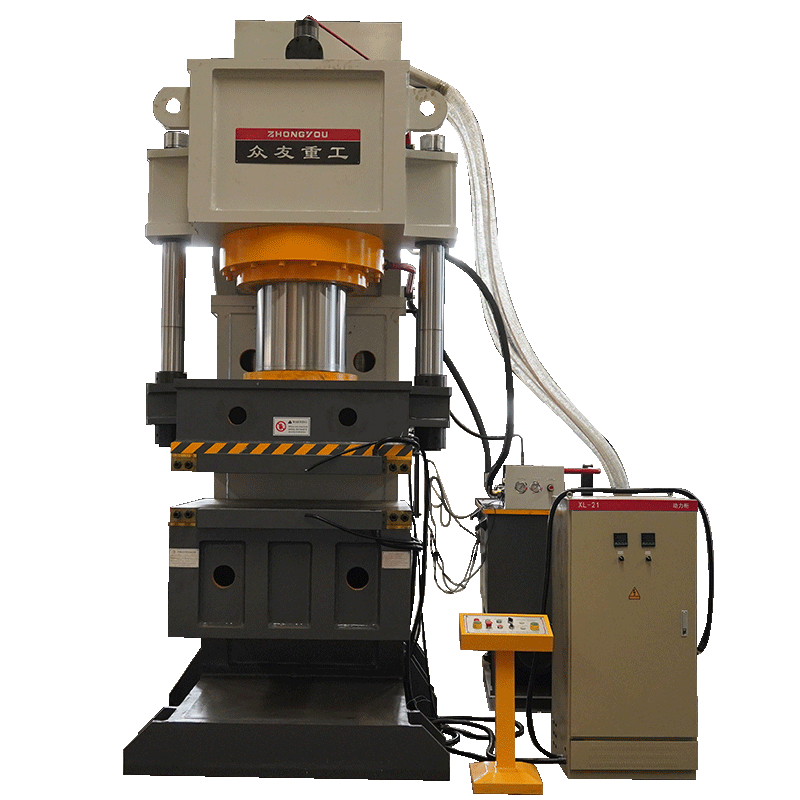

100 tons bearing calibration single arm hydraulic press

Small and medium-sized hydraulic equipment with C-type single-arm structure is used to complete the process of molding, calibrating, and press-fitting of metallic/non-metallic materials by applying pressure through the hydraulic system.

Description

Application areas and process adaptation

Metal processing: shaft parts alignment, bushing parts press fitting, sheet metal stretching/punching/bending/flanging, powder metallurgy pressing, automobile motor assembly, highway sound insulation board stamping, etc.

Non-metallic molding: plastic products, insulation material pressing, glass fiber reinforced plastic septic tank molding (need to cooperate with SMC/BMC material), rubber/ceramic parts molding.

Special process: straightening of I-beam heat-treated parts, bearing press fitting, shaping of long shaft parts, and thin plate stamping and molding.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

Detailed Parameters

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |