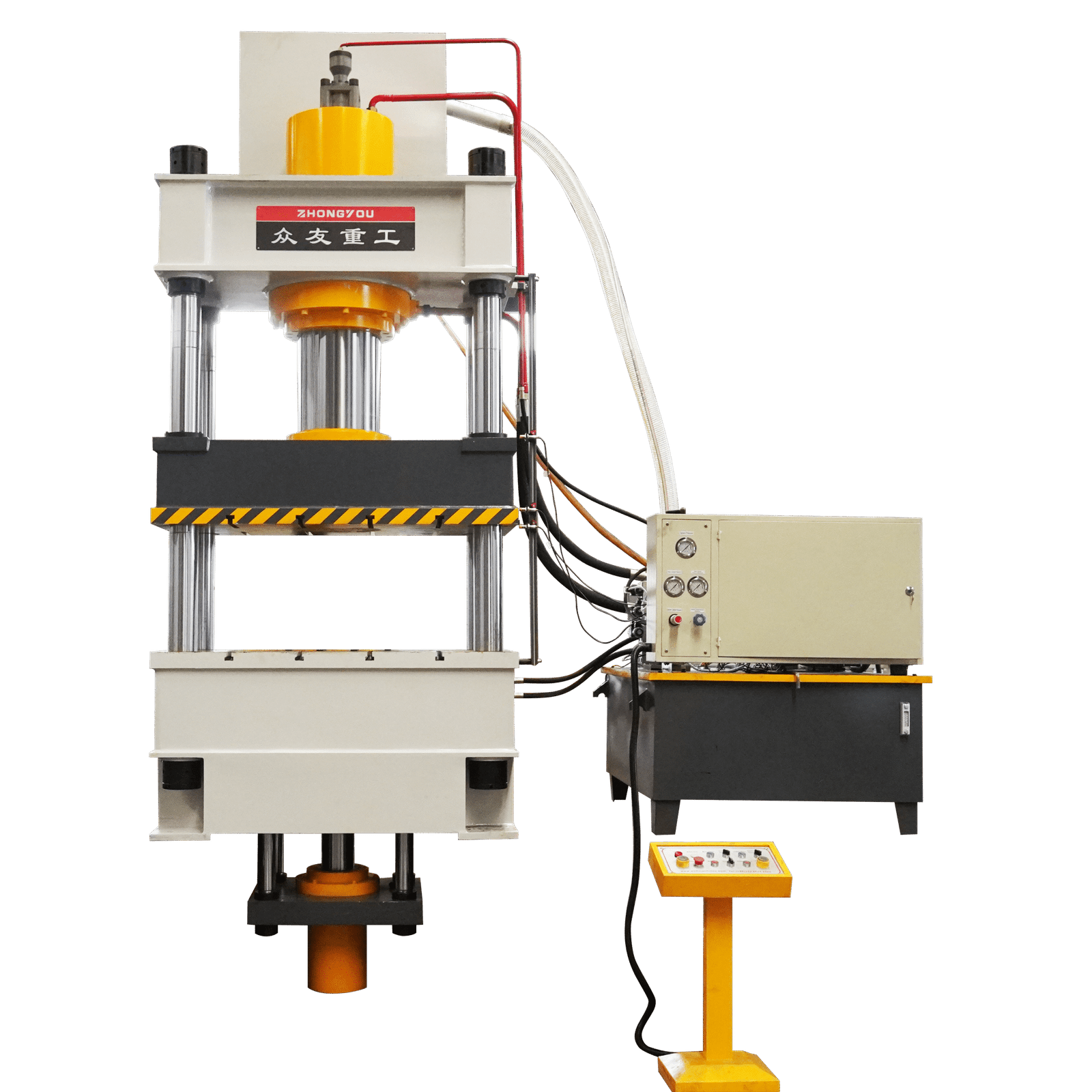

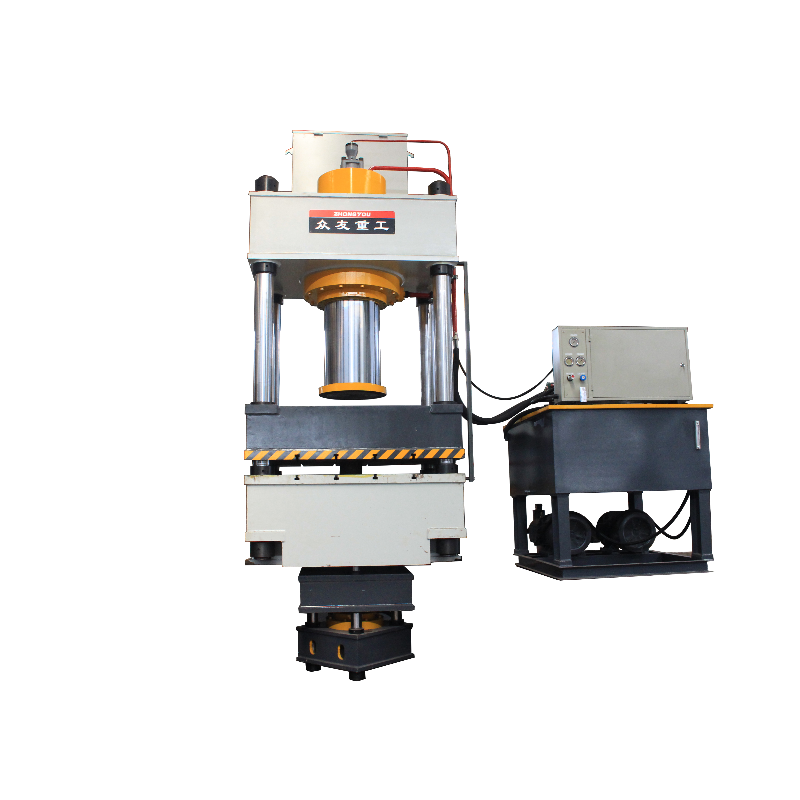

Deep drawing hydraulic press machine 630 Ton

Deep stamping hydraulic press is a kind of machinery and equipment that uses liquid pressure to carry out deep stamping processing.

Description

Deep stamping hydraulic press is a kind of machinery and equipment that uses liquid pressure to carry out deep stamping processing.

High pressure transfer: using the incompressibility of the liquid and the nature of the fluid transfer force, the liquid pressure is increased to a certain level by the liquid pump, and the high-pressure liquid is transferred to the hydraulic cylinder through the pipeline, and the piston in the hydraulic cylinder produces linear movement due to the action of the liquid pressure, so as to realise the strong force transfer required for the deep-pressing process.

Precise control: Equipped with a control system, including hydraulic valves, control panels, sensors and other components, it can control the start and stop of the hydraulic pump, the speed of movement of the hydraulic cylinder, the magnitude of the force, etc. It can accurately control the pressure, speed and stroke of the stamping process to ensure the dimensional accuracy and quality stability of deep-drawn stamped parts.

Stable structure: the machine body is usually welded by high-strength steel plate, tempered and vibration-treated to ensure no deformation in long-term use, and can withstand high pressure and impact in the process of deep stamping to ensure the stability and reliability of the equipment.

Automobile manufacturing: It is used in the deep stamping forming process of metal sheet parts such as automobile cover parts, which can produce automobile parts with complex shapes and high dimensional accuracy, such as doors and bonnets.

Home appliance industry: It plays an important role in the manufacture of metal shells for home appliances, which can realise the deep stamping processing of various home appliance shells and meet the requirements of home appliance products on appearance and performance.

Aerospace: Used in the deep stamping processing of key aerospace parts, it can ensure the high precision and high strength requirements of the parts, providing reliable parts support for the aerospace field.

Views: 0

Compression molding process

Customer Case

Technical Specifications

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Detailed Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |